A few years ago, I wrote about the excitement of a new toy here at EWI. Since then, we’ve gotten several other new toys, but not one as close to my heart as the baby we just unwrapped! EWI recently took possession of a new Harms and Wende RPS100-K12 RFSSW machine! Woohoo! You have no idea what that is, do you? Well, I’ll explain it – but first maybe I can give you some background…

New materials are being invented every day. People want their phones and computers to be lighter, they want their cars to be stronger and more fuel efficient, and they want new gadgets with specifications and features never thought of before. The problem is that all those new things that people want require new materials, and those new light-weight materials and widgets and gadgets often require some way to join them. And often times, those new materials — which have very special microstructures produced in a very special manner — often times don’t like traditional joining processes (particularly, fusion welding processes).

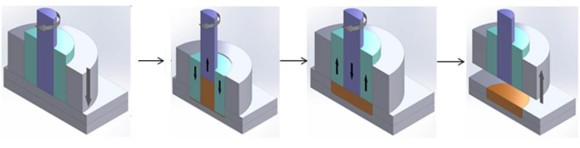

So begins the rule of the solid-state welding processes (Rule? OK. Too strong. Maybe “era”? “Trend”? No. I like rule.). In solid-state welding processes the part doesn’t melt when welding, or any material that did melt is forced out of the resulting joint. Examples of solid-state welding include linear or rotational friction welding, ultrasonic welding, and friction stir welding. Which brings me to our new toy! The Harms and Wende RPS100-K12 RFSSW is a Refill Friction Stir Spot Welder (RFSSW), a version of Friction Stir Welding. In this process, a rotating pin and sleeve clamp down on the sheets being joined. The friction between the pin and sheet raises the temperature of the sheets to a point just below their melting temperature. When the sheets are in this plastic condition, the sleeve plunges into the sheet and the inner pin lifts up, allowing material to flow into the sleeve. At a pre-determined plunge depth, the inner pin forces the material back down as the outer sleeve is retracted. A schematic of this process is shown below.

RFSSW is a new, growing technology with myriad uses anywhere people want to join sheet metal at low temperatures. From automobiles to consumer electronics to aerospace applications, the possibilities are endless. Should you want more information about this exciting new technology, or if you just want to come see our new toy, please feel free to contact me at [email protected]. I like sharing.