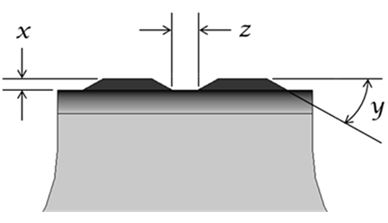

Weld joints in electronics and biomedical devices are getting smaller and more complex, while reliability remains a high priority. This is certainly true when it comes to manufacturing battery cells. EWI Engineering Group Leader Mitch Matheny has written Knurl Design Optimization for Foil-to-Tab Welding in Lithium-ion Battery Cells to discuss EWI’s innovations in ultrasonic metal welding tool design for joining thin aluminum and copper foils to battery tabs. EWI’s work focuses on the geometry of the knurl, which grips one side of the weld joint and provides the required mechanical motion. By taking an in-depth look at three critical knurl features, we’ve come up with an optimized design that increases weld strength, decreases foil damage, and reduces the amount of energy required. To read this paper, click here.