Advancing industrial technologies through world-class engineering solutions

EWI empowers industry leaders to overcome complex manufacturing challenges and seamlessly integrate new processes to bring products to market more quickly and efficiently. With unmatched expertise and advanced manufacturing technology resources, EWI is an integral extension of our clients’ innovation and R&D teams. We can assist you at any stage in your process—or collaborate with you from start to finish.

NDT and Evaluation Training from EWI -- ONLINE!

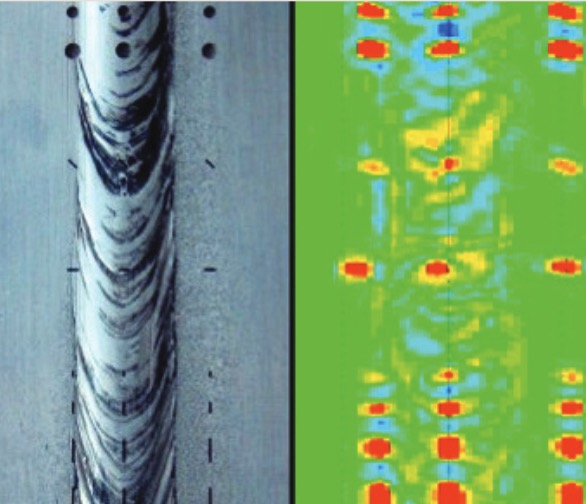

Do you want to want to gain a fundamental understanding of NDT technology and best practices? Sign up for EWI’s self-paced, online course, FUNDAMENTALS OF NDT, and learn on your own schedule! You’ll be introduced to surface inspection, radiography, and ultrasonics, plus receive a micro-credential certificate in nondestructive testing and 22.5 PDH credits upon course completion.

More InformationAdvanced Technology

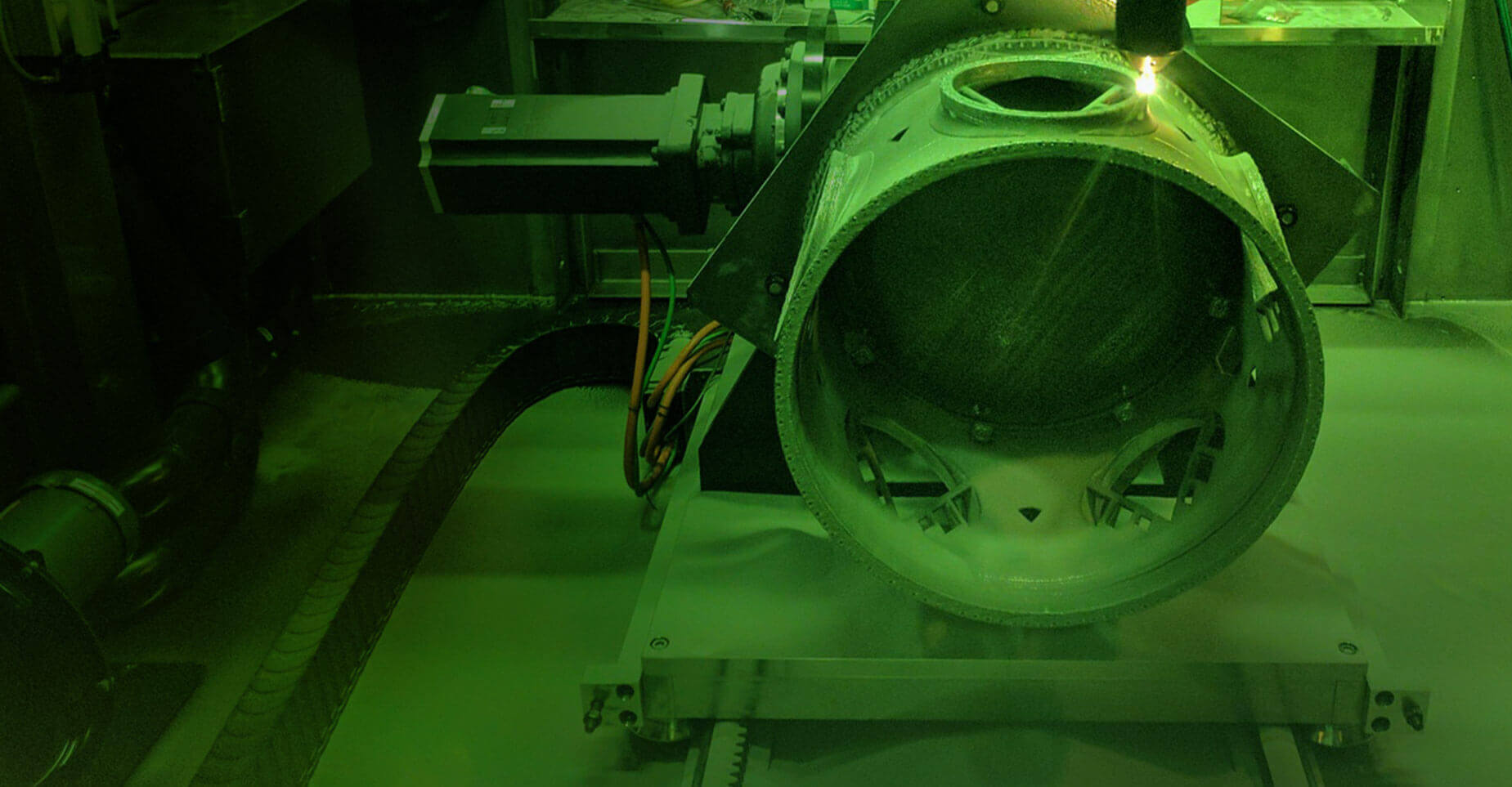

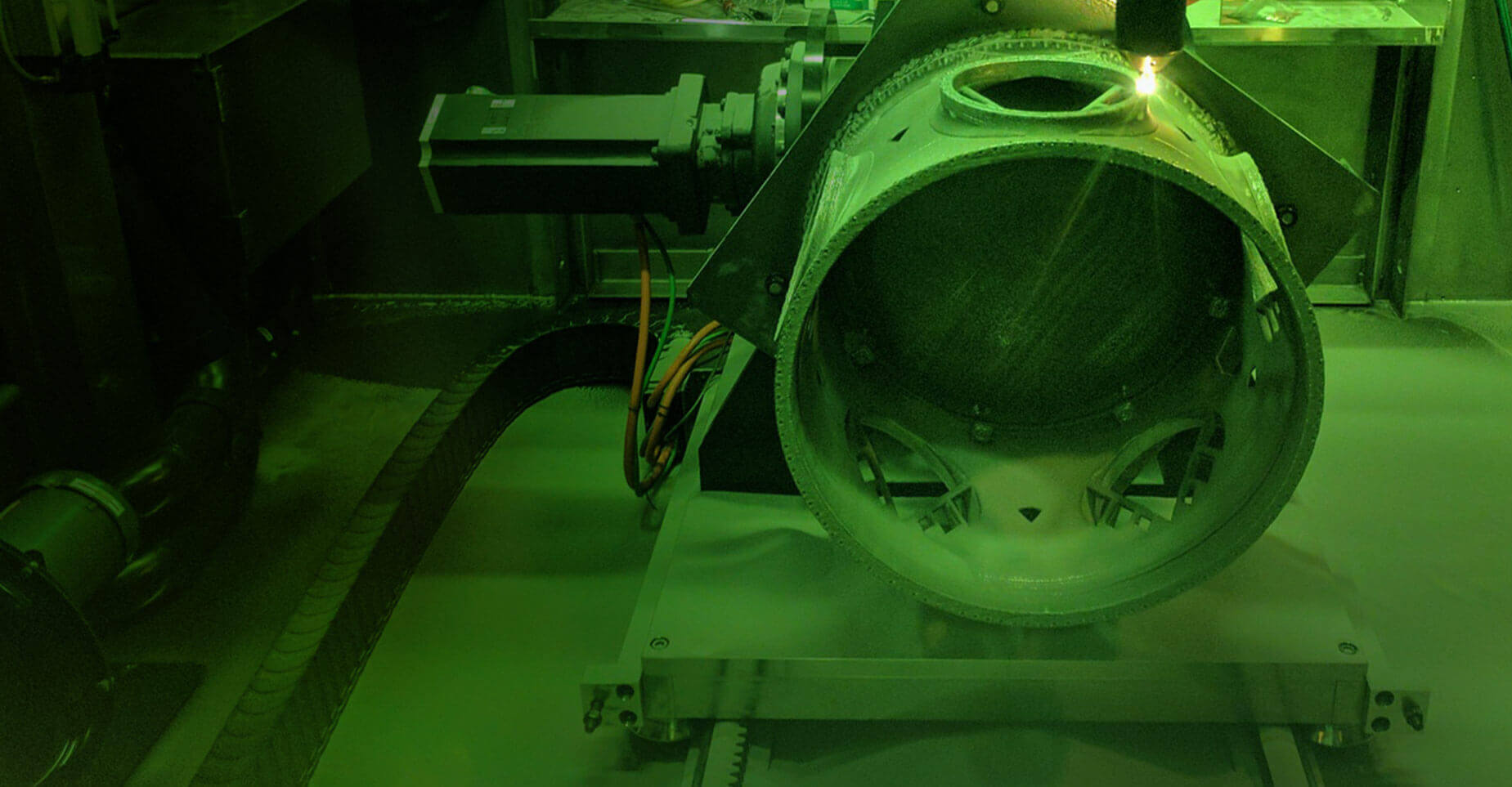

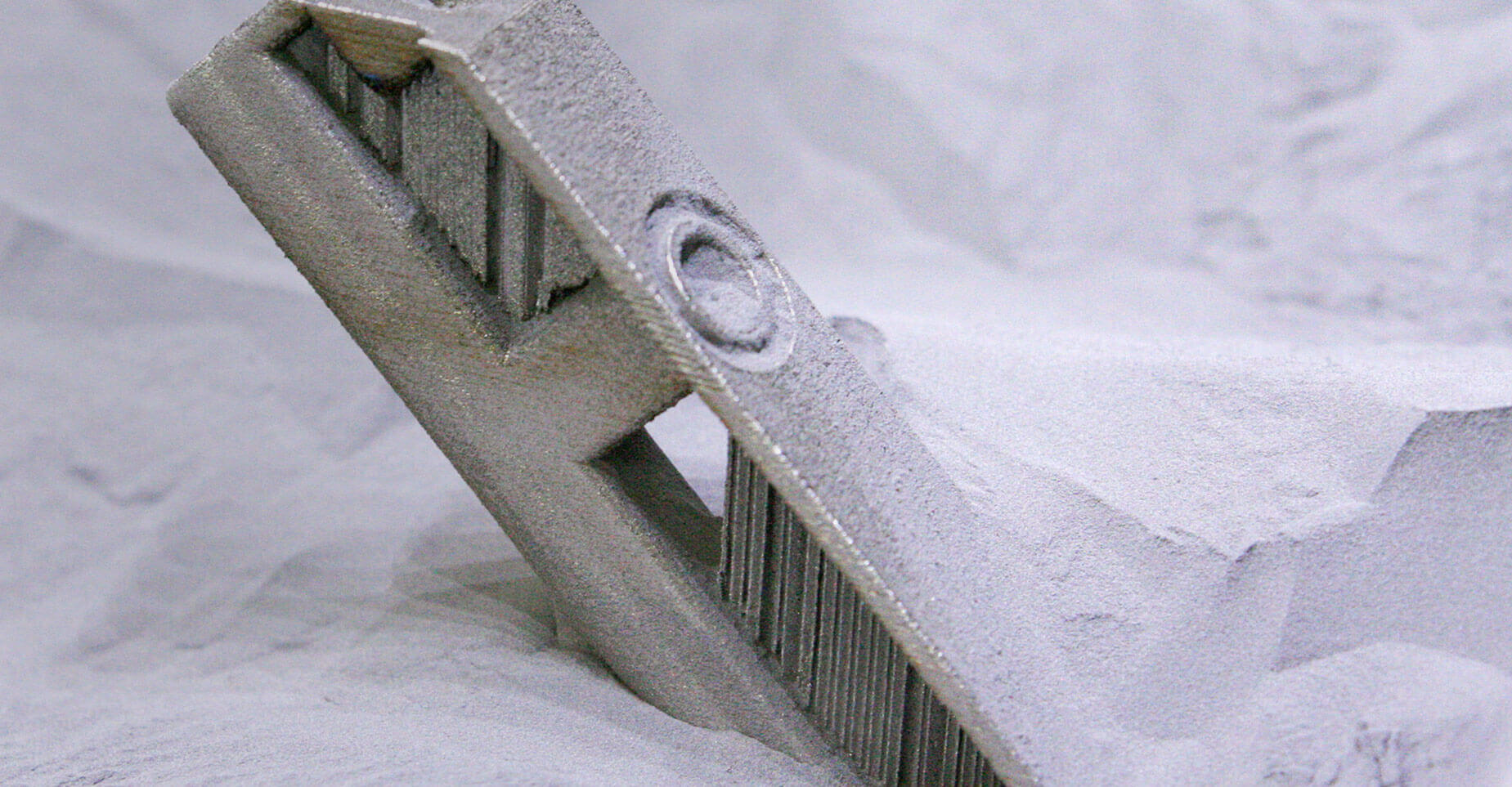

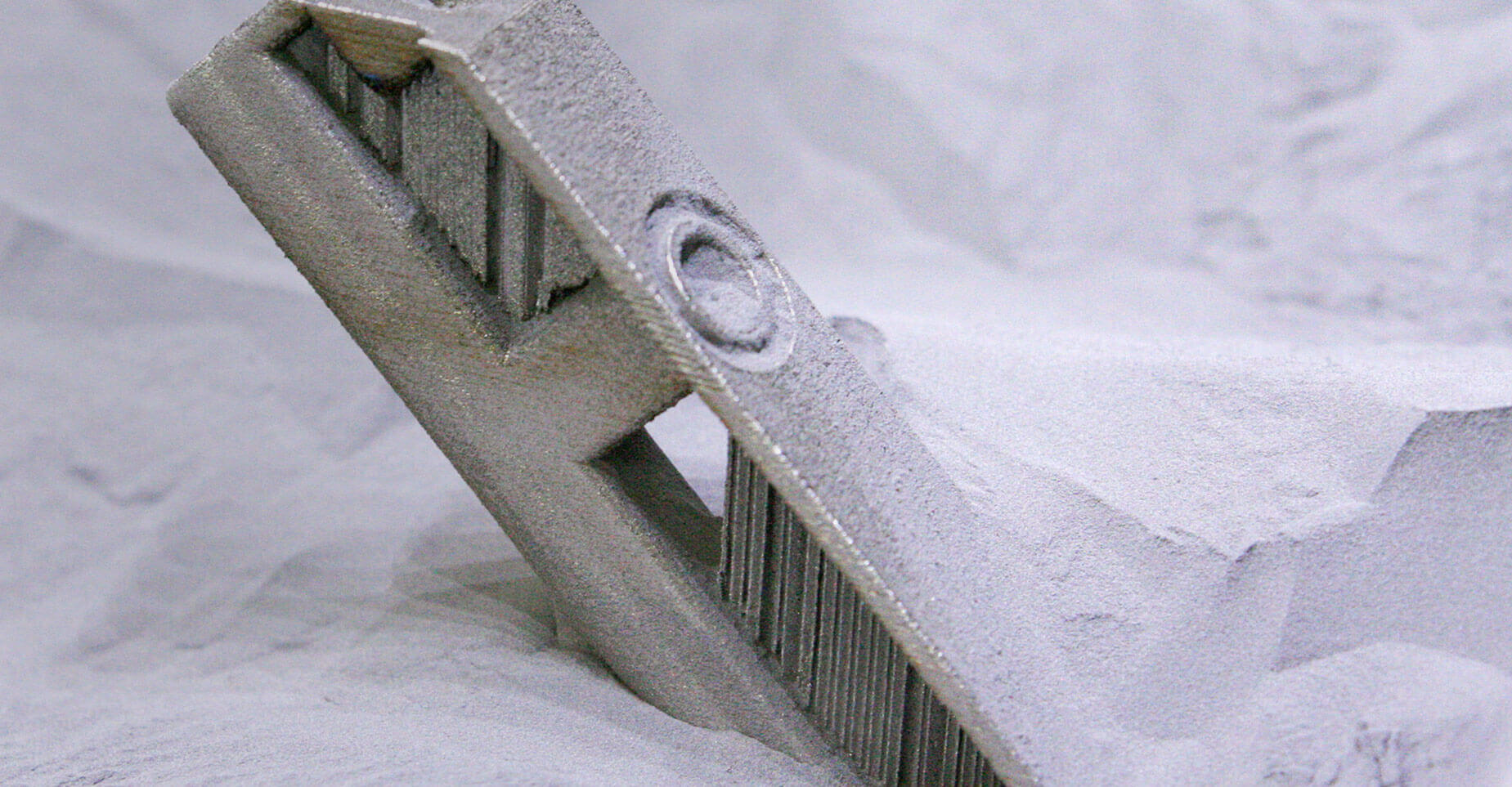

EWI is the only independent engineering consultancy with comprehensive labs and advanced manufacturing technology resources dedicated specifically to production process development and improvement.

EWI’s high-impact capabilities include:

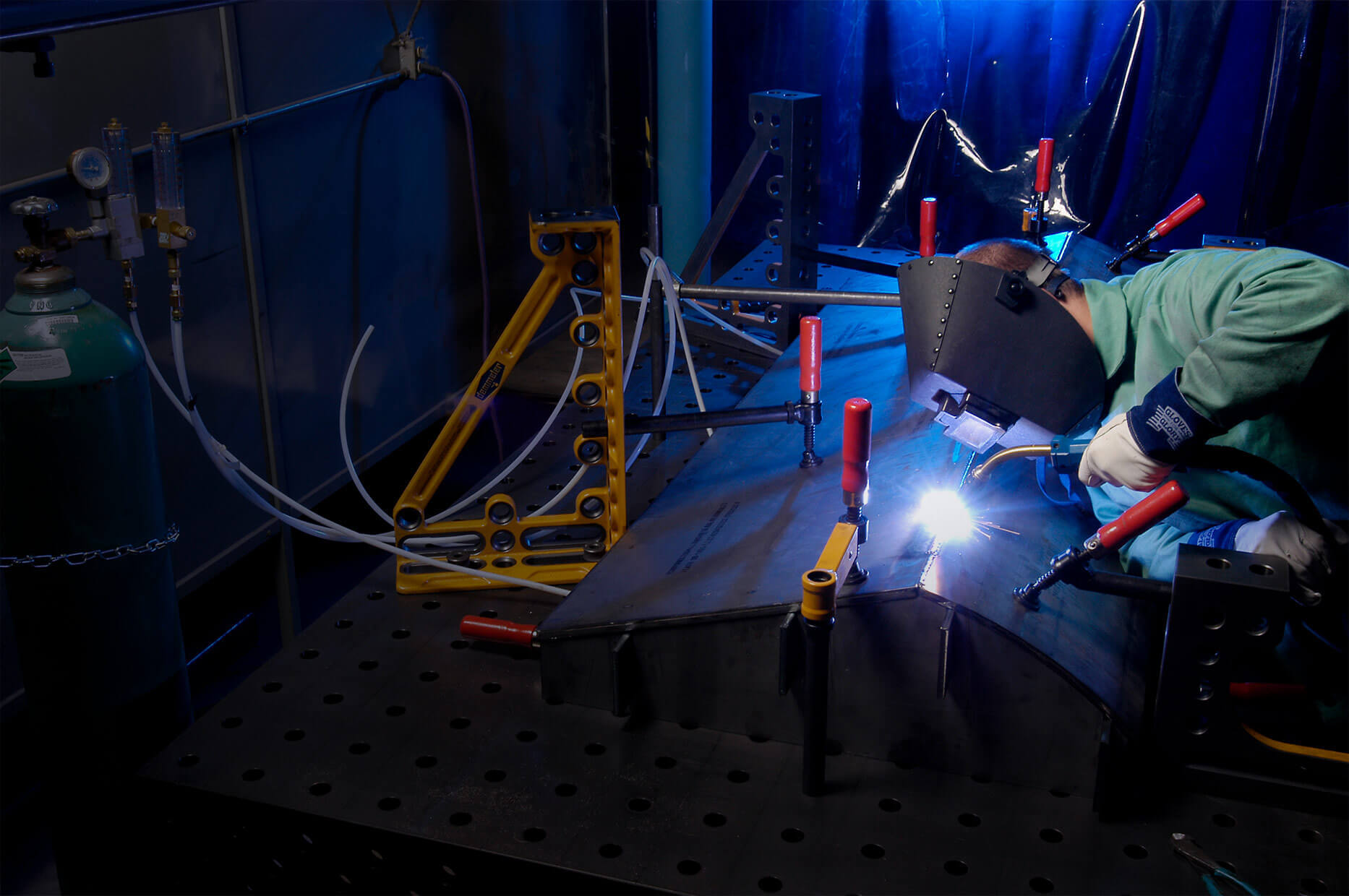

Welding & Joining

Additive Manufacturing

Metal Forming

Advanced Automation

NDE & Inspection

Materials Engineering

Testing & Lab Services

Latest News