The rapid advancement of solid-state laser technology (fiber lasers and disk lasers for example) has peaked the interest of a lot of companies who are looking for increased welding productivity. One of the most common questions that I receive from our customers is ‘So how much laser power do I need to weld my parts?’ This is a good question considering that the cost of a laser is heavily dependent on how much power it is capable of producing.

My answer to most of these people is ‘it depends’. There are a lot of factors to consider when thinking about exploring laser welding as a production process. For example, what type of materials are you welding, how thick is the material, what is the joint configuration, do you need full-penetration or partial-penetration, and too many more to list in this blog.

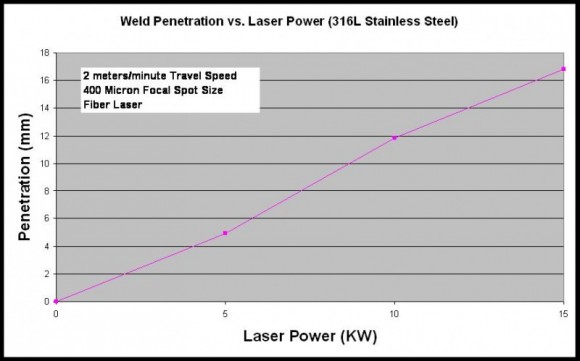

The good news is that there is a general ‘rule-of-thumb’ that can be used to make an estimate on how much laser power you need to weld most carbon and stainless steels. Here it is: At 2 meters/minute (80 IPM) travel speed, you will need about 1-kW of laser power for every millimeter you need to penetrate. For example, if you are making a butt-weld on 6-mm stainless steel, you would need around 6-kW of laser power to get the job done if traveling 2 meters/minute.

Again, there are a lot of factors to consider, but if you are just looking to get a feel for how much power you might need for carbon and stainless steel this information should get you close.