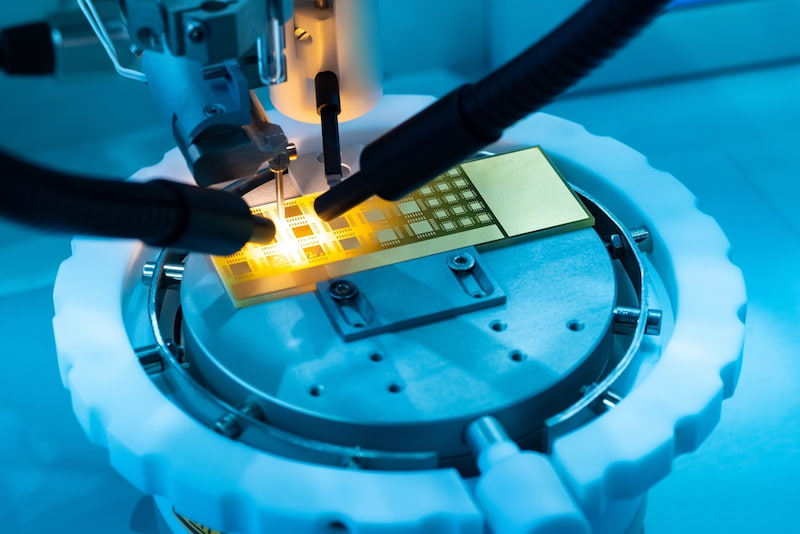

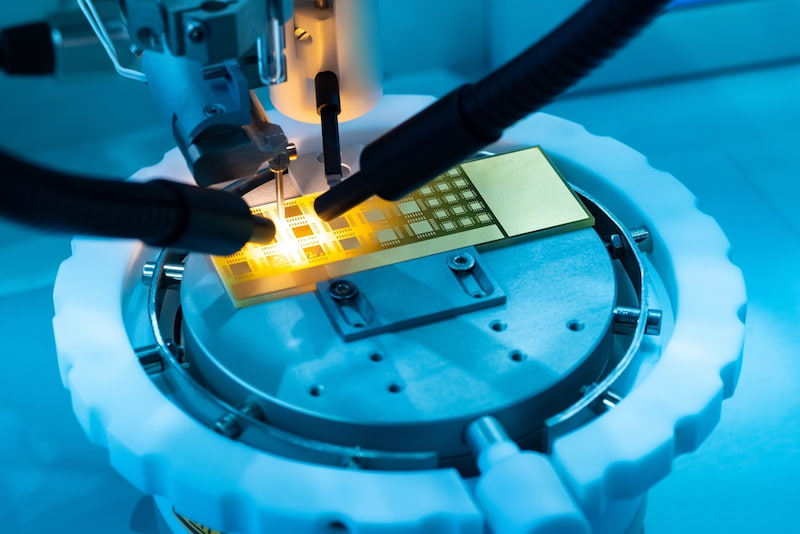

Consumer Electronics

Success in consumer electronics manufacturing requires tight design-to-market timelines, streamlined production processes, and minimized costs. Understanding the interdependencies of these elements can make or break a new product.

EWI helps companies develop consumer electronics manufacturing solutions and efficiently adopt them. We apply our cross-industry experience and process expertise to address your unique challenges in complex and dissimilar material joining applications, battery welding and inspection, and nondestructive evaluation (NDE).

Count on Us for Electronics Engineering Solutions

The consumer electronics industry is driven by demand for products that are lighter, more durable, less expensive, and faster—all with longer battery life. Manufacturers of personal electronic devices and appliances need to respond fast to shifts in the market while operating on slim margins; that isn’t easy to do when managing costs for specialty materials, product innovation, or even re-shoring.

EWI delivers consumer electronics engineering services that enable the world’s top electronics manufacturers to improve their manufacturing processes for high-volume production and increased speed to market.

Electronic materials engineering is our specialty. We’ve solved myriad problems for applications involving ceramic, plastic, glass, titanium, and unique materials. Additionally, we have technology expertise in welding, joining, automation, evaluation, and additive manufacturing for electronics. Our cross-disciplinary experience in industries like medtech and automotive is a unique advantage to our clients.

We don’t just provide electronics manufacturing consulting—we’re beside you from initial feasibility testing through final quality assessment. Our team will work with you to validate solutions to your biggest electronic product development challenges.

Industry Sectors and EWI Initiatives

- Battery tab welding

- Battery weld assessment

- Dissimilar materials welding

- Laser welding and processing

- Resistance welding

- Ultrasonic welding

- Polymer processing

- Leak testing of electronics enclosures

- Package sealing solutions

- AI for quality assessment

- Waste reduction

EWI can help you identify the right technology, develop ideal processes, and implement your innovations.

Want to learn more?

Check out EWI’s research, video demonstrations, and service overviews for the electronic product industry.