Automotive & Transportation

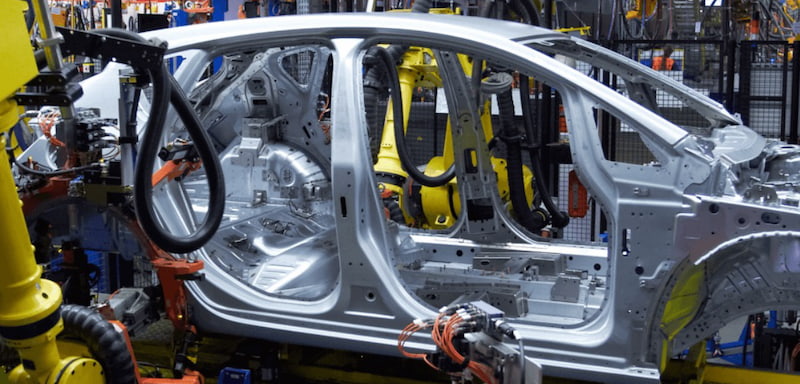

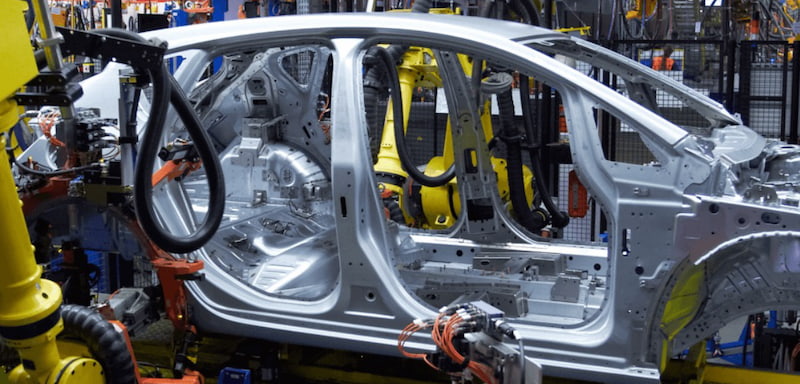

In the auto industry, doing more with less is imperative for success. Solve your most complex manufacturing challenges with advanced automotive engineering services from EWI.

EWI develops and adapts production technologies and processes that enable vehicle manufacturers and suppliers to incorporate new materials, elevate product design, and increase manufacturing efficiency while meeting sustainability goals.

What to Expect from EWI

EWI has decades of experience helping the automotive industry develop stronger, lighter cars; improve vehicle safety; and comply with new regulations. Our long-term collaborations with major OEMs and Tier 1 suppliers give you a unique advantage in your advanced automotive engineering programs. Our engineers act as an extension of your team.

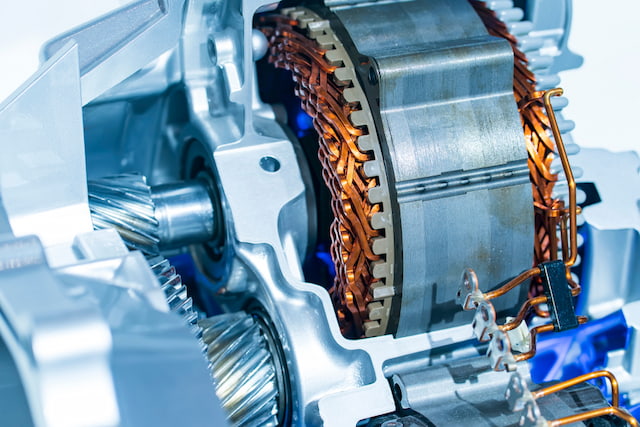

Our areas of specialty include advanced materials science for automotive applications, nondestructive inspection methods, vehicle electrification innovations, automotive additive manufacturing, and all joining technologies. Whether you are a supplier or an OEM, EWI will help you develop and validate manufacturing technologies and processes.

The best way to benefit from EWI’s diverse offerings is to get our team involved early in the design and development of your new applications. By helping your organization validate new technologies and processes, manufacturing procedures can be streamlined.

Key services include:

EWI Initiatives

- ESG for manufacturing

- E-mobility

- Vehicle lightweighting

- Dissimilar metals joining

- Power electronics

- Vehicle propulsion

- Thermal management

- Next-generation vehicle crash modeling and analysis

EWI can help you identify the right technology, develop ideal processes, and implement your innovations.

Want to learn more?

Check out EWI’s research, video demonstrations, and service overviews for the automotive/ transportation industry.