Manufacturing strategies in the 21st century are driven by the need to bring new and differentiated products to market at increasingly accelerated rates. Newer designs, application of advanced materials, and reduced development times propel manufacturers to employ innovative approaches for characterizing performance. To this end, integrated computational materials engineering (ICME), an analytical framework used to develop sophisticated techniques for predicting material and product performance, is increasingly deployed across the industrial spectrum.

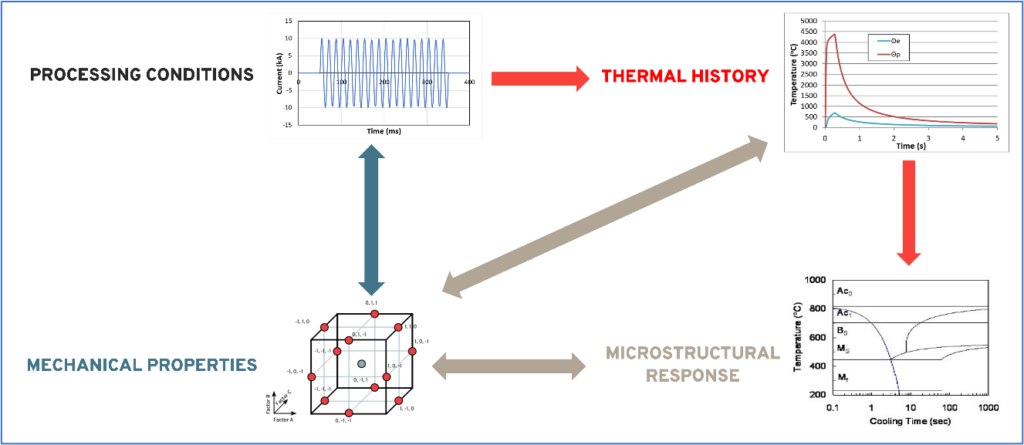

Over the past year, EWI has developed a strategic initiative to apply ICME tools for predicting the performance attributes of welded structures. These approaches take advantage of EWI’s broad process knowledge combined with an array of analytical, numerical, and data science tools to systematically define attributes such as thermal history, microstructural response, and mechanical performance.

Our engineering teams have reviewed many available analytical and numerical constructs and are devising effective solutions to a range of applications. Under the direction of Senior Technology Leader Jerry Gould and Data Science Director Alex Kitt, the results of their work are being published in an ongoing series of papers on the application of ICME at EWI.

Part 1 of our series, which includes an introduction to ICME and several papers covering approaches to correlating processing conditions to thermal excursions, is now complete. To access any of the papers in Part 1, click on the titles below.:

- Overview of Integrated Computational Materials Engineering (ICME) Tools Used at EWI by Jerry Gould

- Analytical Methods for Predicting Thermal Excursions for Continuous Joining Processes by Jerry Gould

- AM Analytical Methods for Predicting Thermal Excursions for Continuous Joining Processes by Alex Kitt

- Analytical Tools for Assessing Thermal/Mechanical Response During Single-shot Welding Processes by Jerry Gould

- Thermal Analysis Using Finite Element Methods by Amin Moghaddas

Papers in Part 2 of the series, “Correlating Thermal Response to Evolving Microstructure,” will be published in 2024.

If you would like to discuss EWI’s ICME tools, please contact Jerry Gould at [email protected].