EWI’s Green Laser Capability for Electrification, Copper Welding, and DED

By Jacob Hay

The use of industrial lasers for manufacturing has been gaining popularity for decades as laser sources have improved in efficiency and reliability. A properly selected laser energy source combined with the right system can offer great flexibility, providing varying energy densities, wavelengths, and configurations for countless applications. EWI’s laser lab continues to be on the cutting edge of industrial applications through both collaboration with the laser industry and internal development to push the limits of what can be done.

In the past decade, new electrification applications have increased steadily, necessitating high-speed welding of copper for electrical interconnects as well as motor and power electronic connections. Copper and other highly reflective materials can be challenging in laser welding: after all, copper is often used for mirrors to reflect, direct, and shape high-power laser beams.

There are several techniques available to enable the welding of these highly reflective materials, one of which is the use of shorter wavelengths such as the 515-nm green wavelength laser produced by a Trumpf laser. Trumpf recently consigned a TruDisk 2021 green laser systems to EWI for use on research and development projects. EWI has integrated the system into its laser laboratory, enabling the laser to be used in varying applications including welding and directed energy deposition (DED).

The Green Laser Advantage

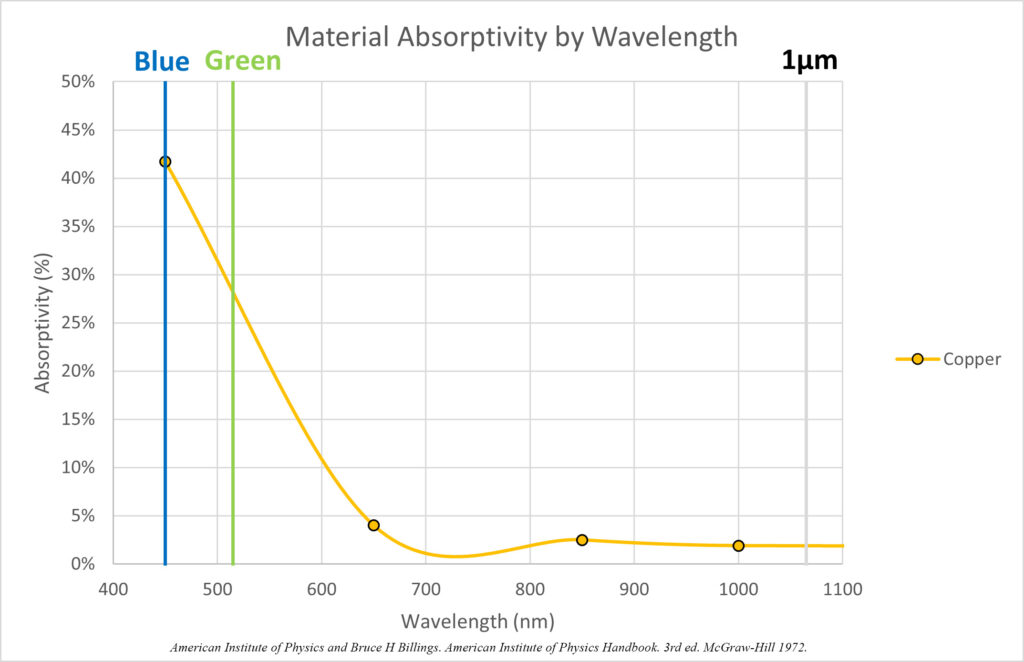

The advantage of the 515-nm wavelength green laser can be illustrated by demonstrating the absorptivity of varying wavelengths on copper material. As seen in Table 1 below, the absorptivity of copper begins to increase at a wavelength of about 650 nm and steadily increases as the wavelength is shortened. The absorptivity at a one-micron wavelength (“near infrared”), the most common industrial laser wavelength today, is very low for copper, just under two percent.

Table 1. Laser Absorptivity Base on Material and Laser Wavelength

This trend of increasing absorptivity continues as the wavelength is reduced into the ultraviolet wavelength range and beyond. However, laser technologies that are currently available in those wavelengths are limited in continuous power and affordability. The advantage of using visible wavelengths is the ability to interact effectively with material at lower-power densities to create conduction mode welds. This ability can be very advantageous for many electrification and DED applications.

The EWI/Trumpf System

The potential capabilities and advantages of visible wavelength lasers have been investigated for years in lab environments at low powers, due to the lack of high-power laser sources. Within the past five years, multiple companies have developed visible wavelength lasers with industrially suitable powers, capable of welding and other processing applications. Trumpf is the primary company manufacturing a green laser in powers greater than one kilowatt. They currently offer laser systems at 515-nm wavelength up to three kilowatts, using as small as 50-micron fiber diameters.

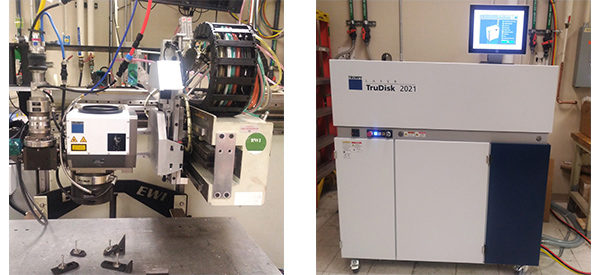

The integration of the Trumpf TruDisk 2021 green system with EWI’s laser welding station is shown in Figure 1. This workstation provides a linear motion platform to complement the Trumpf galvo scanner (PFO 20-2) for high-speed welding, as well as a motion solution for an alternate DED capability (D70 Laser Metal Deposition head) on the same motion system. The D70 Laser Metal Deposition head with optics designed to accommodate the 515nm wavelength and deliver metal powder to the work surface for DED applications.

Copper Laser Welding Development

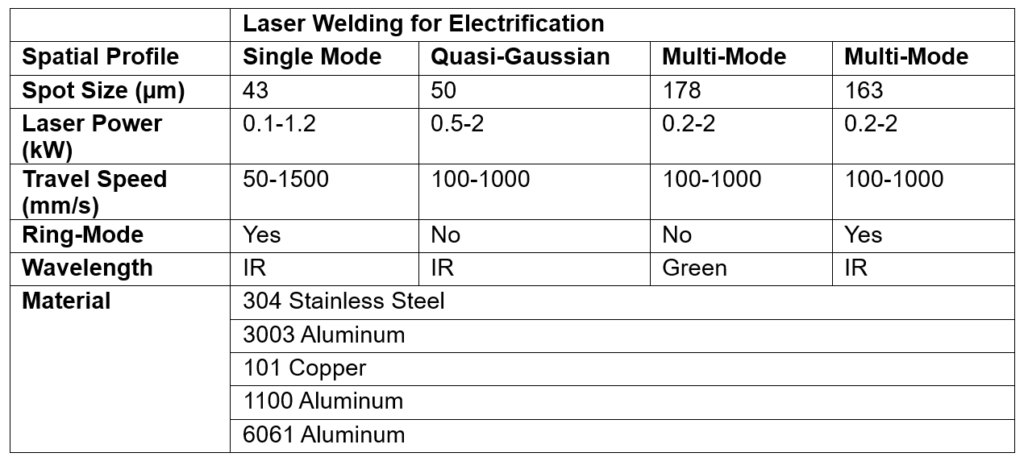

The 515-nm green laser wavelength can offer an advantage in certain applications but is not the answer for all copper welding needs. EWI is currently conducting an internal research and development project to evaluate the benefits and capabilities of the green laser compared to other laser sources. The project is currently looking at a variety of laser sources including multi-mode and single-mode beams, one-micron and 515 nm green wavelengths, fixed beam and wobble motion and copper, aluminum, and stainless-steel materials in various configurations. An outline of the ongoing project is shown below in Table 2. EWI plans to use the baseline data from this research project to guide laser selection decisions for future applications, projects, and consulting needs.

Table 2. Internal Research and development Project Outline

The next project planned for the green laser system is a copper-based DED development project to investigate the capabilities and benefits of the green laser system for DED applications. This work is planned to begin with blown powder DED using a copper alloy and continue on to copper wire DED applications.

Note: References to specific equipment and/or materials are for informational purposes only. Any reference made to a specific product does not constitute or imply an endorsement by EWI of the product or its producer or provider.