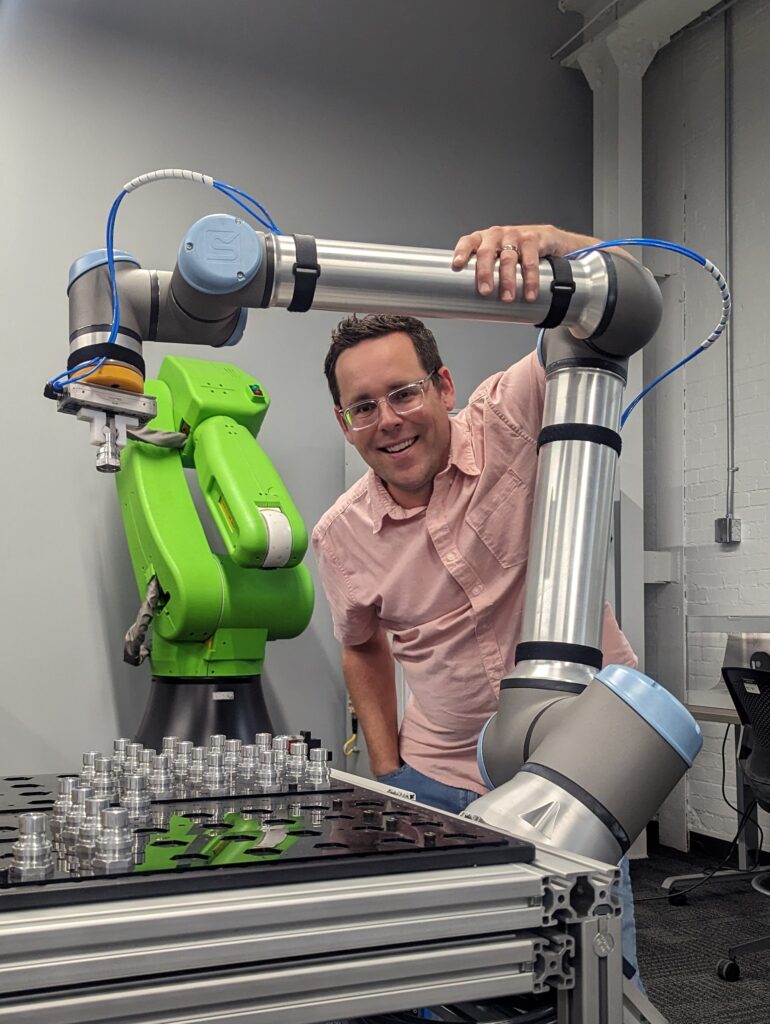

Last month, EWI Automation Program Manager Matt Malloy attended Modex 2024 in Atlanta, where he checked out the hottest new technology geared toward streamlining manufacturing productivity. He was especially impressed with the range of solutions available to small and medium-sized manufacturers (SMMs) in terms of flexibility and cost effectiveness. Here are Matt’s top ten technologies from the show that will revolutionize the way SMMs operate, ranked from most affordable to high end:

- Real-time shop floor productivity dashboards ($) offer a dynamic way to monitor and optimize manufacturing operations. They provide instant access to critical metrics such as throughput, utilization, and downtime, empowering teams to make data-driven decisions on the fly. Customizable displays and intuitive interfaces enable seamless collaboration and communication among team members, ensuring alignment toward common goals. Whether it’s tracking production targets, identifying bottlenecks, or optimizing resource allocation, these dashboards can be indispensable tools for driving continuous improvement and maximizing efficiency.

Example from Modex 2024: Peakboard

- Automated carton sealers ($) have transformed the packaging process by automating the tedious task of box sealing. Simple setup and operation eliminate the need for manual taping, saving valuable time and labor costs. These systems can ensure consistent and secure packaging on both ends with every application. For businesses of all sizes, investing in automated carton sealers not only enhances efficiency but also improves overall product presentation and customer satisfaction.

Example: BestPack Packaging Systems

- Automated pallet wrappers ($) streamline the palletizing process by efficiently wrapping loads with precision and consistency. They adapt to both standard and irregular-shaped configurations, ensuring optimal containment and stability during transportation and storage. Features such as variable wrapping speeds and customizable wrapping patterns offer versatility to meet the demands of diverse manufacturing environments and schedules. By reducing labor costs and minimizing film waste, these machines deliver tangible savings while enhancing shop floor productivity. Say goodbye to manual wrapping … and no more getting dizzy while circling the pallet!

Examples: Lantech, Phoenix Stretch Wrappers, Robopac

- Vision systems ($$) revolutionize quality control by automating inspection tasks and detecting defects with unparalleled accuracy. Utilizing advanced imaging technology and intelligent algorithms, they analyze product characteristics in real-time, identifying flaws, inconsistencies, and deviations. From surface defects to dimensional irregularities or missing components, vision systems provide comprehensive inspection capabilities across a wide range of applications. These systems, integrated seamlessly into production lines or standalone inspection stations, ensure product integrity and compliance with stringent quality standards, ultimately enhancing customer satisfaction and brand reputation.

Examples: KEYENCE CORPORATION, Cognex Corporation, Datalogic, SICK Sensor Intelligence

- Low-cost autonomous mobile robots ($$) (AMRs) offer SMMs an affordable entry point. These versatile robots navigate independently within factory environments, performing tasks such as material handling and parts delivery. With intuitive programming interfaces, low-cost AMRs are easy to deploy and integrate into existing workflows, eliminating the need for complex infrastructure or specialized training. These robots can optimize workflow efficiency, reduce manual labor, and enhance worker safety.

Example: MūL Technologies

- RFID technology ($$) revolutionizes inventory management by providing real-time visibility and traceability of products throughout the manufacturing process. By tagging items with passive RFID tags, manufacturers can track their movement and location, reducing the risk of lost or misplaced inventory. RFID readers placed strategically throughout the facility capture data seamlessly and instantaneously, enabling accurate inventory counts, stock replenishment, and order fulfillment. Whether it’s raw materials, work-in-progress, or finished goods, RFID tracking enhances operational efficiency, streamlines supply chain logistics, and enables proactive decision-making for optimized inventory management. The technology may be applied as part of a standalone system or integrated with your current ERP/MRP system.

Examples: RMS Omega Technologies, CYBRA

- Automated box erectors ($$$) streamline the packaging process by automating the assembly and sealing of cardboard boxes. They eliminate manual labor, improve efficiency, and reduce ergonomic strain on operators. These machines deliver consistent results for both standard and custom-sized boxes with precision and speed. These systems offer both purpose-built and cobot-based options that can accommodate diverse packaging requirements and production workflows.

Examples: Combi Packaging Systems LLC, BestPack Packaging Systems

- Automated benchtop bagging systems ($$$) enable industrial packaging on a smaller scale. They offer precise and efficient solutions for a wide range of bagging applications ranging from powders to small parts. With customizable bag sizes and sealing options, these flexible systems adapt to diverse packaging requirements, ensuring optimal presentation and protection. They can reduce manual labor, minimize packaging waste, enhance productivity, and boost profitability while improving overall operational efficiency.

Examples: PAC Machinery, Pregis

- Autonomous pallet movers and jacks ($$$$) have revolutionized material handling operations by offering independent, self-propelled transportation and lifting capabilities within factory environments. Whether it’s transporting palletized loads or stacking pallets, these vehicles navigate and perform tasks with precision and efficiency. Advanced safety features and obstacle detection systems ensure safe operation in dynamic environments, minimizing the risk of accidents or collisions. By reducing manual labor and optimizing material flow, autonomous systems enhance productivity and throughput while improving workplace safety and ergonomics.

Examples: Big Joe Forklifts, KUKA, OTTO by Rockwell Automation

- Vertical storage systems ($$$$) optimize space utilization and inventory management by maximizing warehouse capacity within manufacturing facilities. Customizable shelving configurations and automated retrieval mechanisms streamline inventory management workflows and minimize search and retrieval times. By consolidating storage areas and maximizing floor space efficiency, these vertical systems enhance operational efficiency and productivity while reducing inventory handling costs.

Examples: Hänel Storage Systems, White Systems Inc, Vidir, Modula USA

“These top ten technologies represent the forefront of manufacturing excellence,” says Matt. “By embracing these advancements, SMMs can unlock new opportunities for growth, efficiency, and competitiveness in the ever-evolving landscape of modern manufacturing.”

Interested in exploring customized automation solutions for your operation? Whether your facility is small, medium-sized, or large, EWI can help you identify, develop and integrate advanced automation technology customized for your facility. To learn more, contact [email protected].

Note: Any reference to specific equipment and/or materials is for informational purposes only. Any reference made to a specific product does not constitute or imply an endorsement by EWI of the product or its producer or provider.