The energy economy is experiencing a shift away from oil and gas sources as European nations and states, such as California, impose legislation on utilization and sourcing. A primary, would-be displacer of natural gas in the utility space is hydrogen (or chem + hydrogen hybrid fuels). In most cases, the preference of industry would be to utilize legacy infrastructure to transport and store next-generation fuels. However, it is unclear whether the integrity threats associated with the handling of natural gas are equivalent in transportation and storage of high hydrogen fuel stocks.

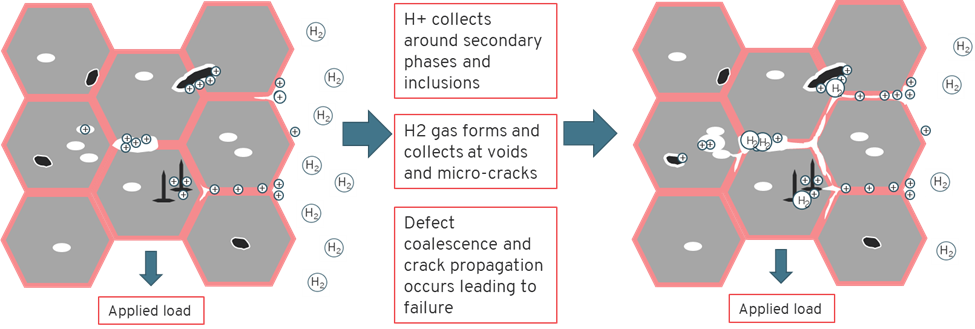

The principal integrity threat from a metallurgical standpoint is a mechanism known as hydrogen embrittlement. Hydrogen gas dissociates into hydrogen protons and infiltrates the microstructure of metallic components. The transported hydrogen collects around defects and degrades mechanical properties. The reduced toughness and load capacity can subsequently lead to brittle fracture and premature failure. The following illustration is a representation of hydrogen infiltration leading to embrittlement:

Schematic depicting the hydrogen infiltration that leads to metal embrittlement.

To ensure safety during conversion to a hydrogen economy, the industry needs to consider the threats associated with the utilization of legacy assets. Due to their metallurgical histories and inherent susceptibilities, many of those materials are potentially vulnerable to embrittlement. Large scale conversion to hydrogen as an increasingly viable energy source highlights the need for the development of new materials with implicit resistance to hydrogen-specific degradation mechanisms. This new frontier will bring new requirements for joining methodologies, materials characterization, monitoring and NDE capabilities, and a thorough understanding of the technical trends in the evolution of the hydrogen economy at large.

To learn more about EWI’s work to address materials and integrity issues within the U.S. energy infrastructure, contact Josh James at [email protected].