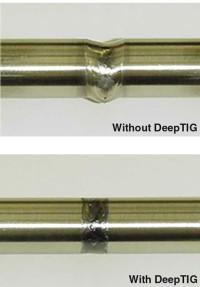

EWI DeepTIG for gas tungsten arc welding (GTAW) helps increase weld penetration by as much as 300%.

These unique metallic oxide compounds are available in a powder form. The powder is combined with a liquid carrier to form a slurry that is then applied to the top face of the joint to be welded.

The metallic oxides in EWI DeepTIG change the weld metal flow such that penetration is increased while the quality of the weld is improved. The product has been developed and tested extensively by EWI and the Navy Joining Center (NJC). Repeated testing has proven that the mechanical properties, weldability, and corrosion resistance are not affected in most of the cases.

For questions on EWI DeepTIG, contact [email protected].

Product Benefits

INCREASED WELD PENETRATION

Increases weld penetration by as much as 300% in most mechanized and automatic applications, greatly improving productivity and reducing weld joint volume.

IMPROVED WELD QUALITY

Reduces heat-to-heat variation in weld penetration, and reduces distortion. It also promotes grain refinement in some alloys.

REDUCED WELDING TIME

Welding time can be reduced by as much as 50% in most applications, dramatically speeding production.

LOWER MANUFACTURING COSTS

Because it reduces heat input and weld time, power and labor requirements are also reduced, thereby lowering manufacturing costs.

LOW RISK, HIGH REWARD

Industrial users in various industries have tested and confirmed the performance and cost savings of EWI DeepTIG.

REDUCED JOINT PREPARATION COSTS

In many applications, full penetration can be achieved with a square edged closed-butt joint reducing joint prep and filler material costs, heat input, distortion, and welding times.

Different compounds are needed for welding different base materials. Currently, we offer EWI DeepTIG in the following varieties:

- SS-7 for stainless steels | View Safety Data Sheet

- NI-139 for nickel based alloys | View Safety Data Sheet

- CS-325 for carbon and low-alloy steels | View Safety Data Sheet

EWI DeepTIG is commercially available from EWI in kit form and in larger quantities.