By Tom Feister

Thirteen years ago, I landed my first job out of school at a company that developed software for sheet metal forming simulations. I did not know anything about sheet metal forming or finite element analysis (FEA) simulation. To get up to speed, I would read through publications from NUMISHEET conferences. It was a great way to get familiar with critical sheet forming topics such as springback and formability limits. As well as learn the best way to test material properties and apply them in simulation. The most interesting part of the NUMISHEET proceedings were the benchmark studies.

The benchmark section is a sheet metal forming simulation competition. Researchers and engineers are given the geometry and process parameters for a sheet metal forming process. The goal is to achieve the most accurate prediction result using numerical simulation. Measured results from physical trials are released after the prediction results have been submitted. This is a great way to compare the software code as well as the skill and expertise of the user.

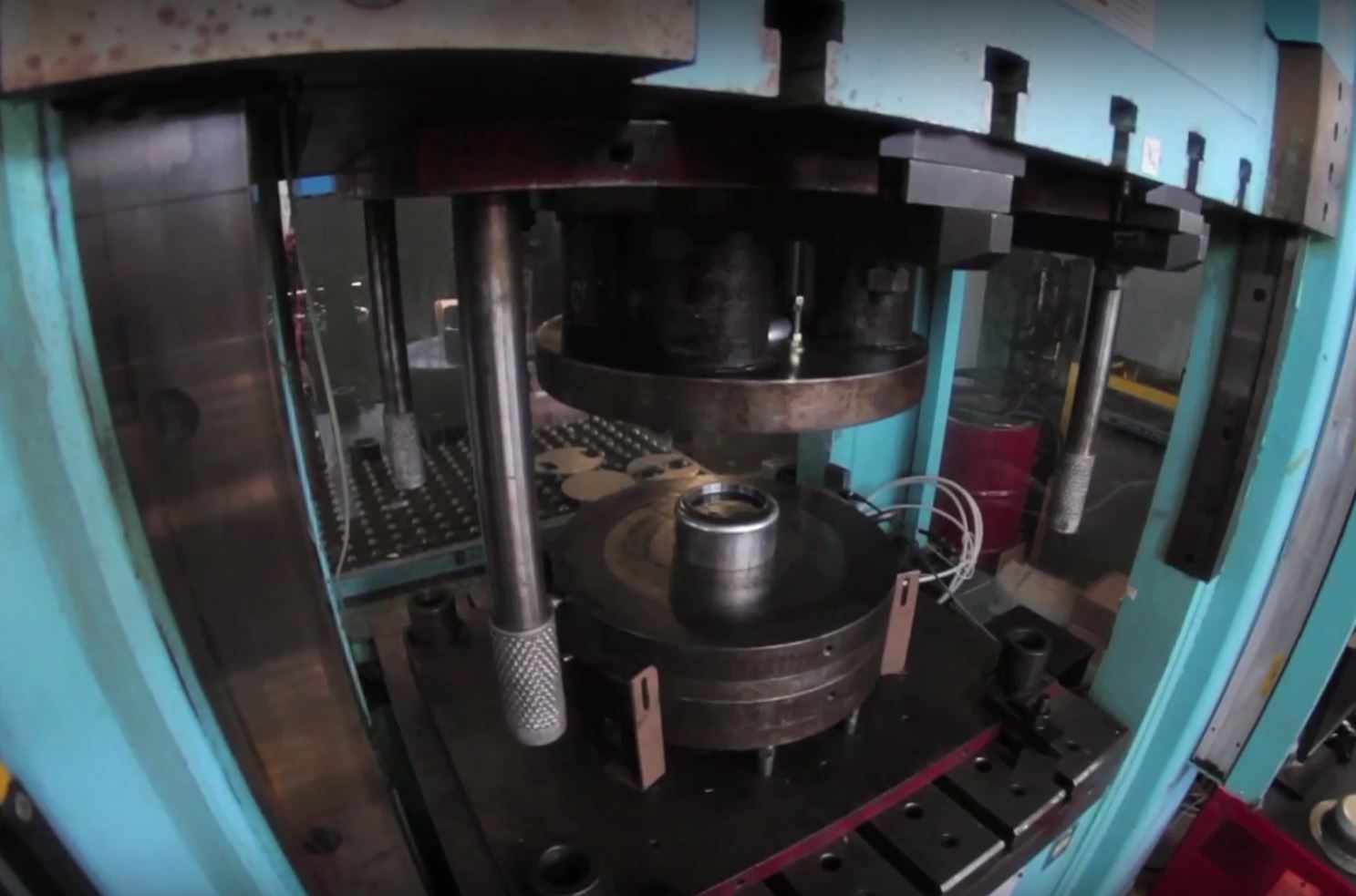

NUMISHEET only occurs every other year. At EWI, we continue to push the limits of simulation accuracy every day. We achieve this through close working relationships within industry and equipped with the latest in simulation software, metal forming presses, materials testing equipment and measuring tools.

- Simulation software: AutoForm, PAM-STAMP, DYNAFORM, DEFORM, Abaqus, and LS-DYNA

- Presses: 300-Ton AIDA servo press and 160-Ton hydraulic press with warm forming test cell

- Materials Testing: Erichsen sheet testing machine, tensile testing, and DIC capability

- Quality measuring Tools: ATOS blue light scanner and ARGUS strain analysis

It is the biggest pleasure of my career to be in the middle of the action. My first year at EWI has taught me a lot about the best FEA software to use for specific applications and exactly how much material testing is necessary to achieve a sufficient amount of correlation. The EWI Forming Center has grown over the last couple of years to offer the highest quality solutions and in a more efficient configuration than ever before. If you have a metal forming issue we would love to work with you to solve it.

Tom Feister is an Applications Engineer in the EWI Forming Center. He can be reached at [email protected] or 614.484.7600.

To learn more about EWI’s forming capabilities, click here.