Additive Manufacturing Consortium

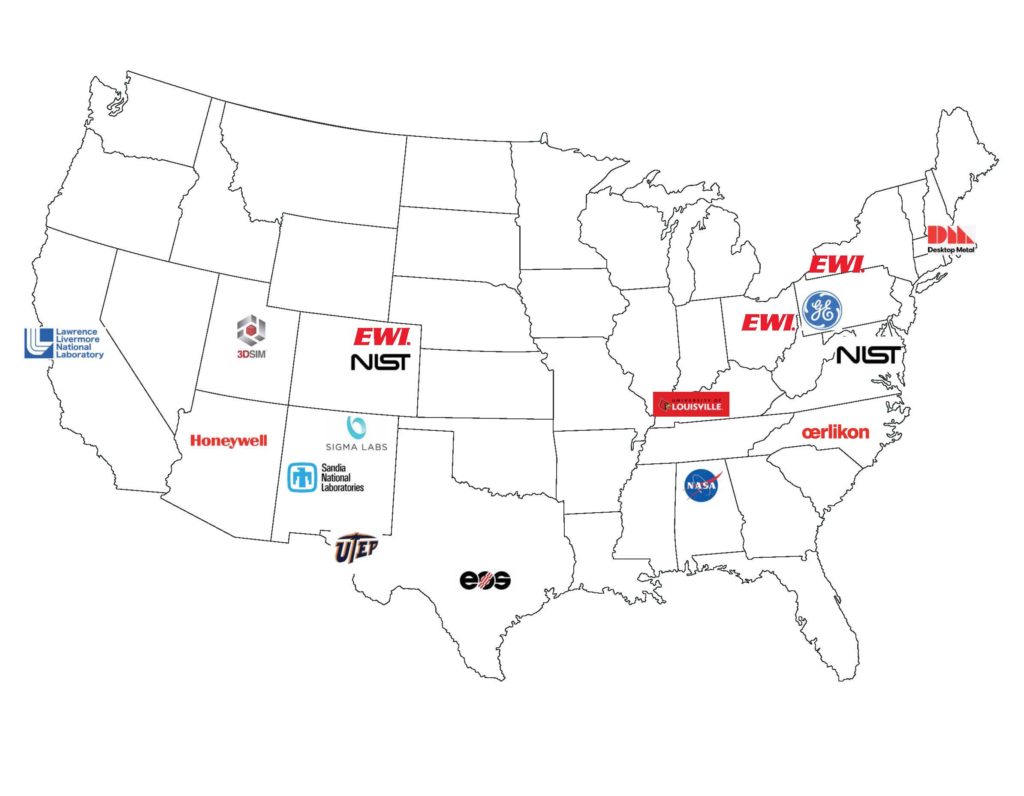

EWI established the AMC in 2010 to accelerate and advance the manufacturing readiness of metal additive manufacturing technology.

Goals

The AMC brings together a diverse group of additive manufacturing (AM) end users, suppliers, researchers, and stakeholders from across the nation to positively impact the AM landscape through organized and focused activities. The four aims of the consortia are to:

To be a platform for collaboration

across global industry, academia and government entities

To execute group sponsored

pre-competitive AM research projects

To partner on government funding opportunities

To provide a forum for discussion and networking among AM professionals

Technical Focus

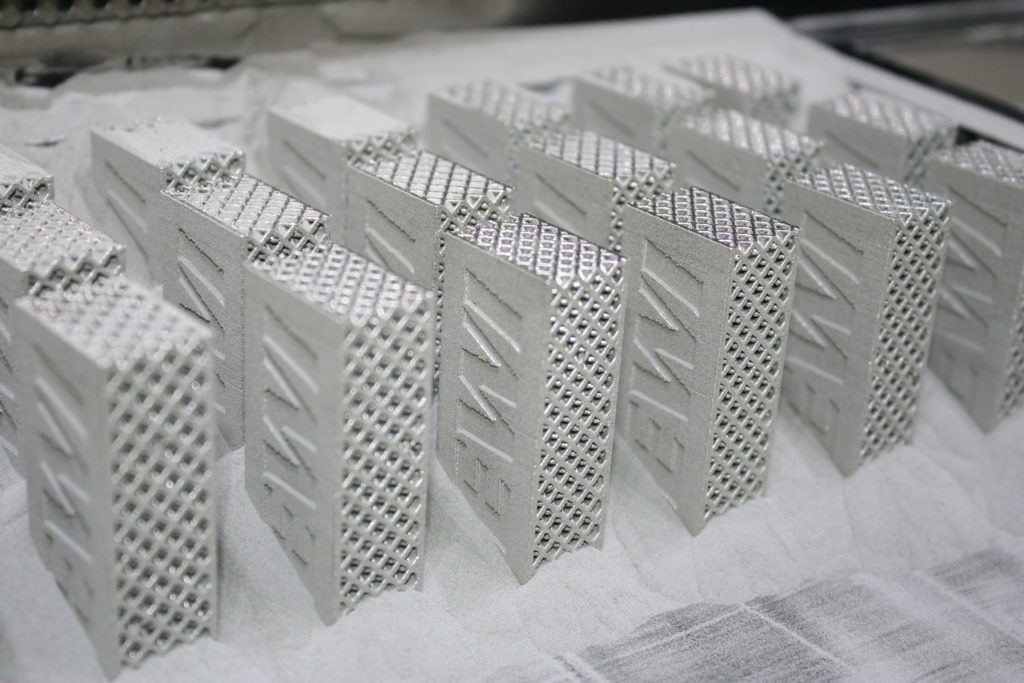

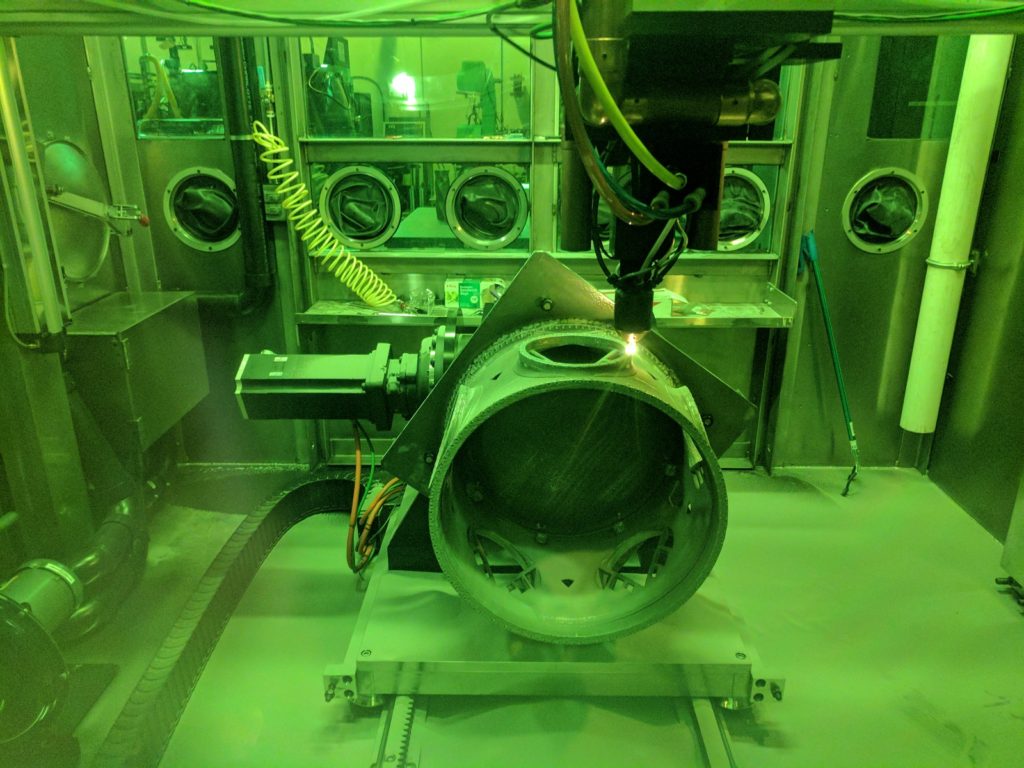

The AMC addresses the technical challenges in advancing additive manufacturing processes such as powder bed fusion and directed energy deposition using lasers, arc, and electron beams, as well as solid state processes such as ultrasonic additive manufacturing.

Members have access to results from previous AMC projects, including:

- Evaluation of Post Process Techniques for AM

- In-Process Monitoring & Defect Rectification: Phase II

- Testing on Current Projects IN 625 and IN 718 and Relating Microstructure to AM Properties

- DED Multi-material/ Repair

- Comparison of Commercially Available AM Simulation Tool

- Stainless Steel Multi-Process AM

Current Projects

The AMC project portfolio is funded annually by more than $2 million in cash and in-kind investments from its members. Projects in 2023 include:

- Continued Assessment of New AM Technologies

- High-strength Aluminum Testing and Characterization of Commercially Available Materials

- AMC Material Properties Database

- Continued Investigation into Low Angle Printing Without Supports

- High Deposition Rate DED Trade Study and Demonstrations

The results of projects are reported at AMC meetings.

Activities

The cornerstone of the consortium is technical discussion and advancement surrounding AM. Members, partners, and invited guests meet quarterly to discuss AM topics. Meetings consist of technical talks, tours, and informal social events to encourage extended conversation and promote collaboration.

Membership

Consortium members come from industry, government, academic and non-profit research organizations.

Exclusive invitation to meetings

Access to technical presentations and development activities

Non-exclusive license to joint intellectual property developed under the AMC.

Members who fund or contribute to a project receive direct access to all data and more frequent updates to project results.

The results of projects are reported quarterly at AMC meetings. In addition, all members are encouraged to present results of other, non-AMC sponsored AM activities, to promote technical interchange. Finally, government and university research partners are available to participate on AMC projects.

To learn more about joining the AMC, contact Mark Barfoot, Director of AM Programs, at [email protected] or 716.710.5597.

For more information about EWI’s additive manufacturing capabilities, click here.

Membership

An annual membership is required to participate in AMC meetings. Currently, the consortium has more than 50 members worldwide including aerospace and heavy equipment manufacturers; powder, equipment, and technical service providers; R&D organizations; government agencies; and academic institutions.

The next meeting of the AMC will be in May 2023. For details about the meeting or for information on how to join the Additive Manufacturing Consortium, contact Mark Barfoot at [email protected] or 716.710.5597.