Corrosion Science & Environmental Testing

Corrosion due to environmental degradation is a natural process. All engineered materials are susceptible to some degree.

In other words, rust never sleeps. But EWI has the strategies and resources for mitigating the natural threat of corrosion in many long-term product applications.

Corrosion mechanisms vary, often act synergistically, and can be initiated by many complex variables. By applying advanced corrosion science principles and testing how materials interact with their environments, EWI helps clients prevent premature product failure associated with corrosion. Trust our experts to solve your corrosion and materials engineering challenges.

With a wide array of corrosion testing resources and expertise in materials characterization and consultation, EWI can assist in addressing corrosion concerns at all stages of a product’s lifecycle. Some examples of our corrosion services include:

- Materials selection for corrosion control and compatibility with environment of use

- Integrity and performance threat identification associated with materials degradation

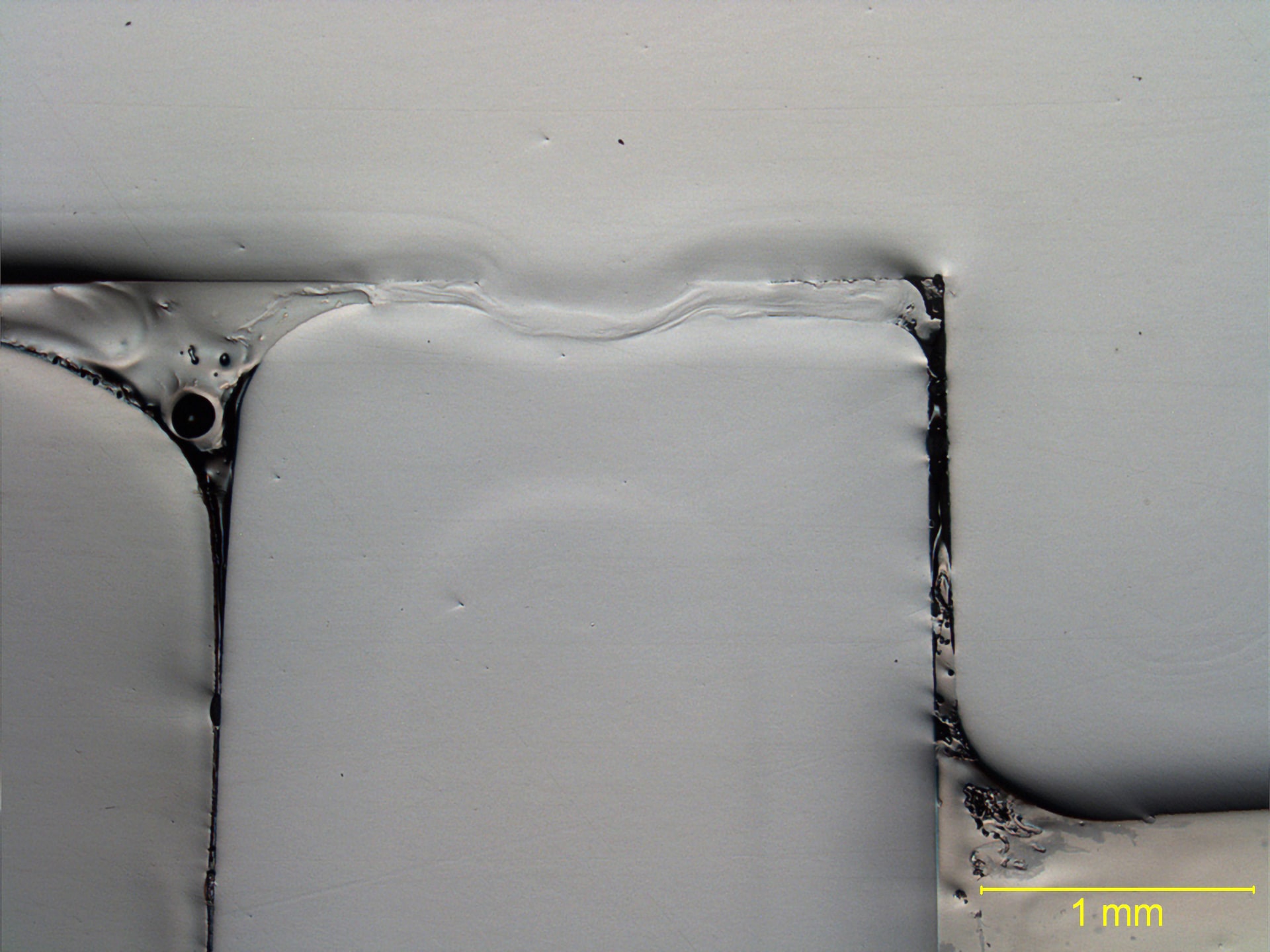

- Environmentally induced fracture mechanics testing (e.g., evaluate risk of cracking due to corrosion)

- Corrosion testing services in our laboratories (e.g., ASTM testing, electrochemical corrosion parameter testing)

- Evaluation of corrosion mitigation strategies (e.g., corrosion inhibitor evaluation, coatings testing)

- Analysis of corrosion-related product failure

- And much more! Explore technical expertise and lab resources below

Why Make EWI Part of Your Corrosion Engineering Solution?

EWI’s corrosion materials science specialists provide decision-making value at every level of product development and implementation — from deployment to maintenance to decommissioning. We focus on design for corrosion resistance and have diverse industrial experience in characterizing corrosion mechanisms. Tackle any material degradation issue by tapping into EWI’s knowledge and resources: an in-house corrosion testing lab, a full suite of fracture mechanics testing equipment, and broad capabilities in complex materials characterization and quantitative microscopy. Make us your trusted corrosion and material engineering consultants today.

Identify. Develop. Implement.

Engineering with Integrity

Since 1984

Whether we’re evaluating a new material, defining the fatigue performance capabilities of welded parts, or identifying the cause of an unexpected failure, our team enables your team to design the required materials and testing specifications ensure successful performance, structural integrity, quality, and safety. We provide the assurance you – and your customers – need for your products.

Need help now? Contact EWI today.