Microjoining

As consumer products become more compact, the challenges of materials joining become more complicated.

EWI provides you with resources to develop and implement the most efficient and reliable microjoining solutions for your applications — quickly and effectively.

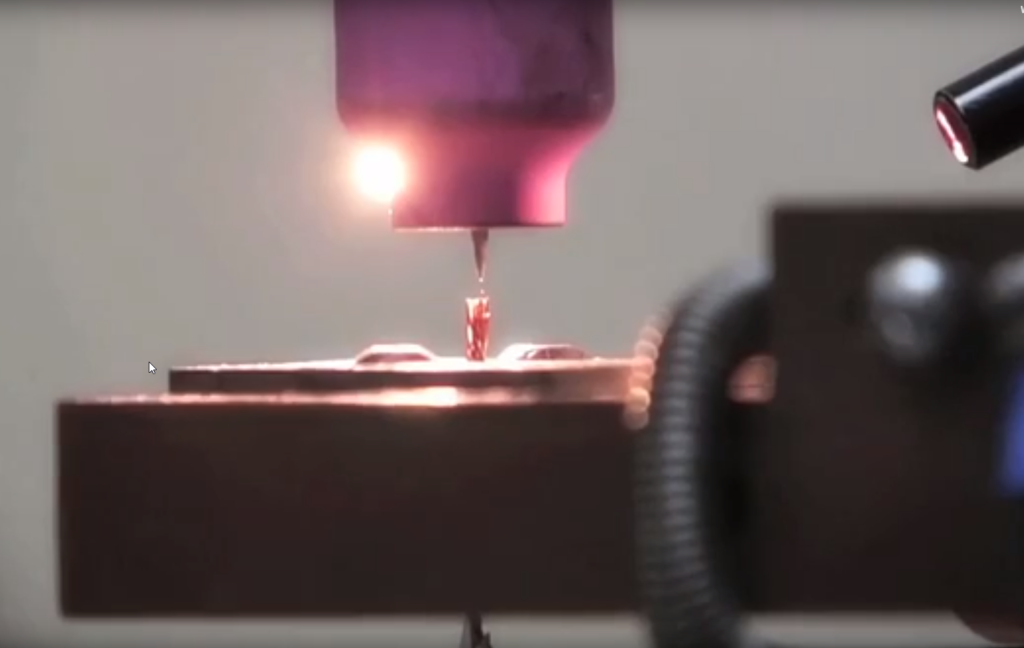

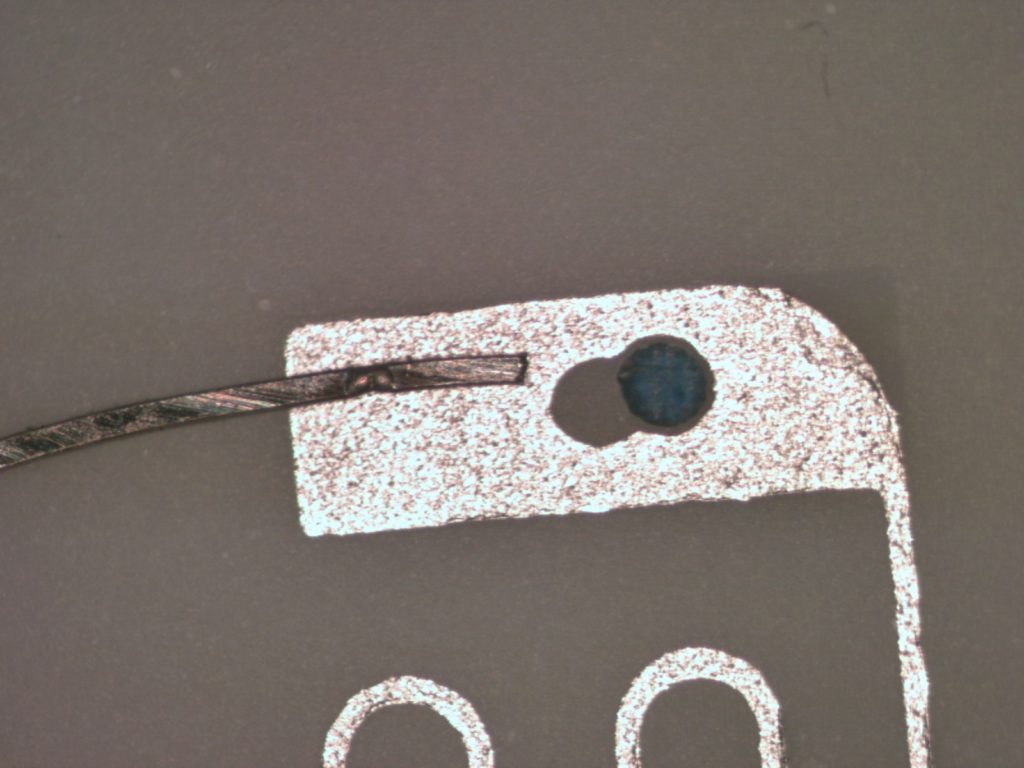

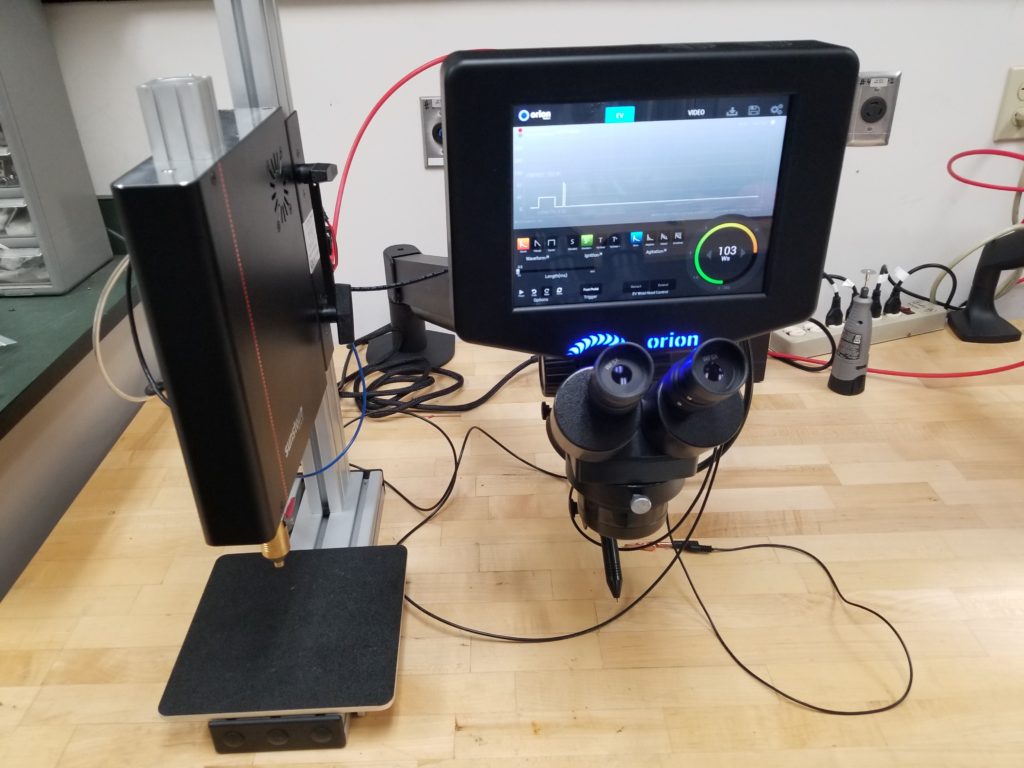

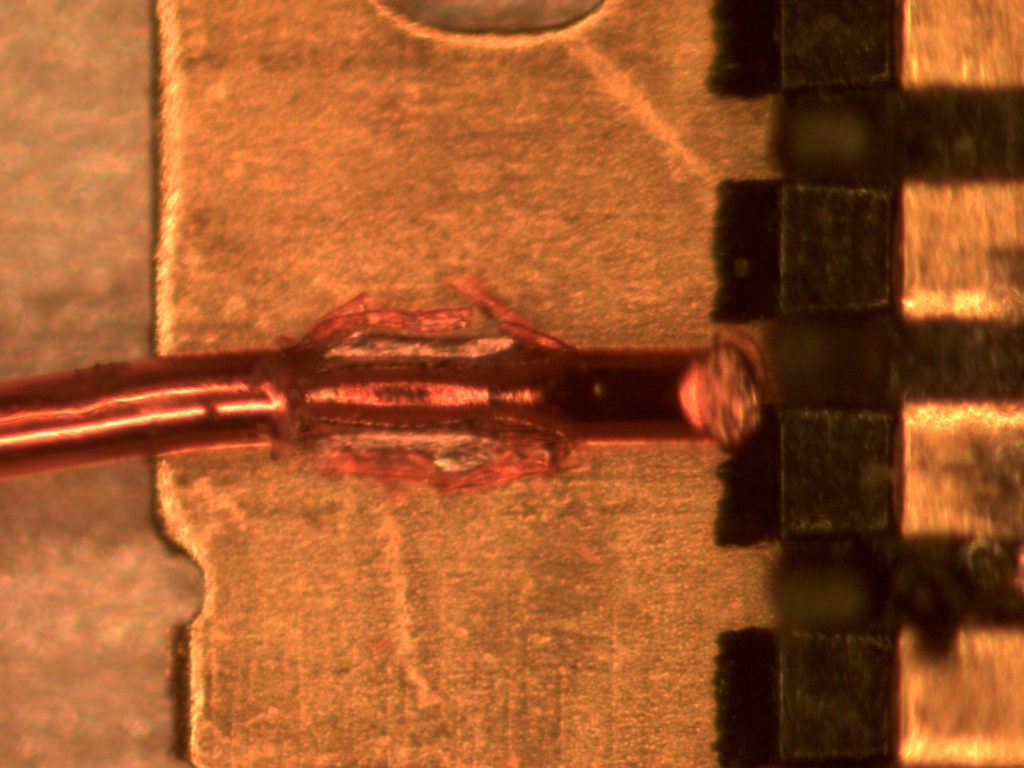

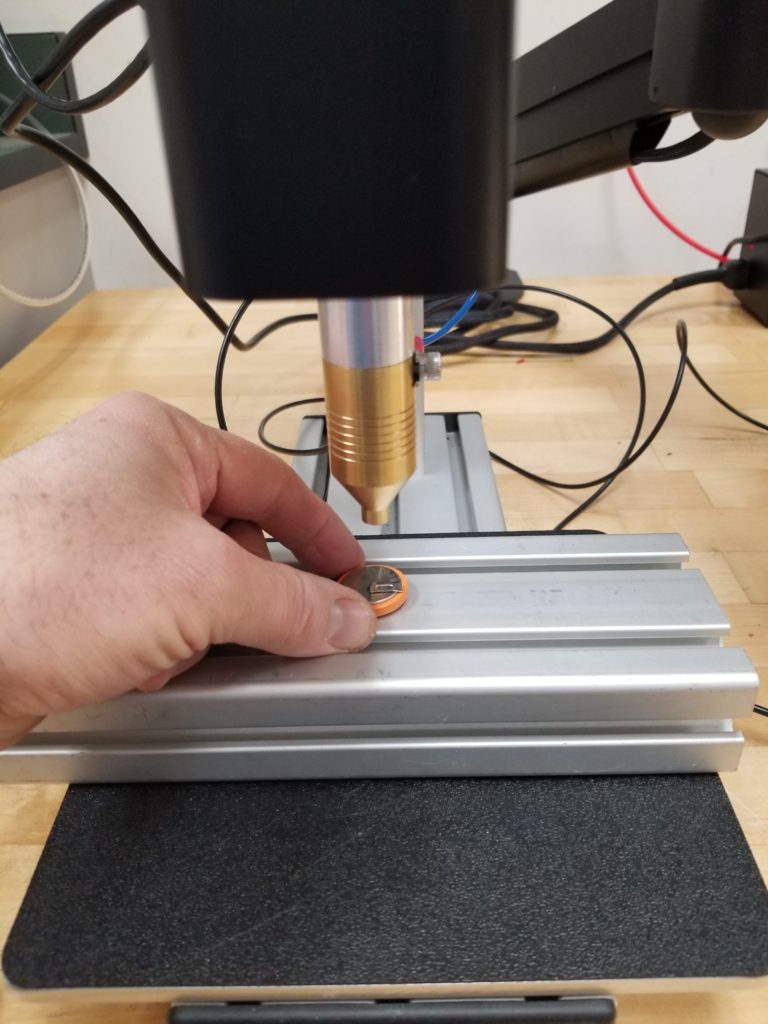

For more than 30 years, EWI has been employing a broad array of joining techniques at the micro level. Our state-of-the-art labs contain equipment for every joining process used in electronic and medical device assembly, including ultrasonic and thermosonic bonders, micro-TIG welders, and precision resistance welders. Resistance reflow soldering equipment and controlled-atmosphere furnaces are also part of this lab.

Our deep expertise in welding technology, metallurgy, materials science, and process design enable our clients to develop comprehensive solutions for joining new products or increasing the efficiency of currently used manufacturing techniques.

Innovations

Over the years, EWI has resolved microjoining issues in applications such as lighting, medical and electronic device connections, miniature motors, automotive components, sensors, superconductors, and fiber optics. Some of our customer solutions have included the following:

- DEVELOPED PARALLEL-GAP RESISTANCE WELDING PROCESS for welding of 56 AWG copper wire to plated copper on polyimide flex circuit, to eliminate solder in an implantable medical device.

- ADVANCED NEW JOINING TECHNOLOGIES for assembly of 3D-printed components and flexible hybrid electronics.

- DESIGNED, BUILT, AND DEMONSTRATED FIXTURING for resistance welding drawn filled tube without exposing core material.

- DEVELOPED RESISTANCE WELDING OF NITINOL WIRES TO STAINLESS STEEL to eliminate a crimp joint and reduce component size.

- DESIGNED AND DEPLOYED A TIG WELDING SYSTEM for smoothing of wire ends for an ear-nose-throat surgical device.

- DEVELOPED A RESISTANCE WELDING PROCESS for replacement of solder joints on a communications satellite application, including mechanical and thermal shock testing.

- EVALUATED SEVERAL PB-FREE SOLDERS FOR SUITABILITY in a high-reliability electrical power transmission component.

Identify.

Develop.

Implement.

WE MANUFACTURE INNOVATION.

When you engage with us to solve your most difficult microjoining challenges, you get the support of every EWI expert with applicable capabilities, across all of our technology groups. We’ll dedicate all the necessary resources to address your issue.

Get Your Microjoining Solution — NOW.

EWI specialists are ready to help you solve your challenge today. Contact the EWI microjoining team to learn more.

View Microjoining Resources

Technical Expertise

- Wire bonding

- Ribbon bonding

- Thermocompression bonding

- Resistance welding

- Parallel-gap welding

- Micro-TIG welding

- Laser welding

- Soldering

- Brazing

- Data collection

- Failure analysis

- In-process monitoring

- Materials science

- Design of experiments

Equipment & Lab Resources

Ultrasonic welding

- Branson Ultrasonics MWX-100 60kHz and 40kHz

- Kulicke & Soffa 4124 gold wire ball bonder

- Orthodyne model 20 heavy wire bonder

Resistance Welding

Amada Weld Tech: power supplies

- IPB-5000A HF inverter

- HF-27 HF inverter

- IS-120 MF inverter

- ISQ-20-6 HF inverter

- HF-2 MF inverter

- DC-25 linear DC

- UB-25 linear DC

- MIB-200A MF AC inverter

- MEA-100A AC

- DP 250 CD

- DP 125 CD

Amada Weld Tech: weld heads

- 300 electromagnetic

- SL-322 electromagnetic parallel gap

- 90A

- 180A (x2)

- 84A

- 80A (x2)

- 50A UB

- 50F RF

Amada Weld Tech: monitors

- ADAM

- MM-370A

- MM-336A (x2)

- MG3

- MM-123

MTI MicroWelding

- Arc-percussion welder

Sunstone Engineering: power supplies

- Linear DC

- CD600DP-A

Sunstone Engineering: weld heads

- WH1187A HF

- WH1125A

Sunstone Engineering: Orion pulsed arc welder

- 250i2 EV system

- 200i v3

- 150s v2

Matuschek

- H9000 HF inverter

- LSK-200 electromagnetic weld head

Amada Weld Tech: micro GTA

- MAWA-300A

Vacuum furnaces

-

- Tube: 3-inch x 12-inch hot zone 1200C

- Tube: 6-inch x 18-inch hot zone 1200C

- Tank: 12-inch cube 1500C

Interested in our microjoining capabilities?

Contact us today to talk with an expert