Aluminum and advanced high-strength steels (AHSS) have been increasingly applied to automotive structural components which allow for improvements in crashworthiness without corresponding weight increases. However, these materials bring along challenges of controlling or compensating springback in design and production phases.

Excessive springback causes fit and finish issues and is very difficult to eliminate or reduce in production. Therefore, a reliable prediction of springback is important to reduce springback and compensation efforts before the formed part reaches production.

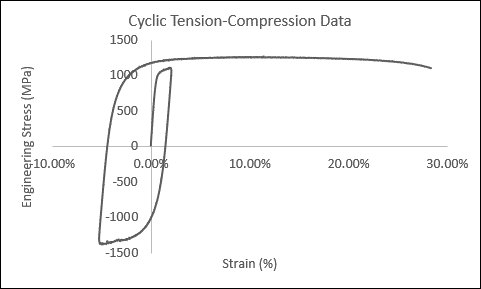

EWI developed a cyclic tension-compression fixture and test method to establish the kinematic hardening material model to be used with the Yoshida-Uemori model. The Yoshida-Uemori model can accurately model springback behavior and based on EWI’s own internal testing can predict springback within 0.5 degrees of experimental testing.

Questions about EWI’s cyclic tension-compression testing? Contact Laura Zoller, Applications Engineer ([email protected], 614.484.7600).