Emerging materials such as high-strength aluminum alloys, advanced high-strength steels (AHSS), and GEN3 steel have been increasingly applied in sheet metal forming components. These materials are known to have unique elastic and plastic material behaviors which create new challenges for engineers and designers. One of the behaviors is springback.

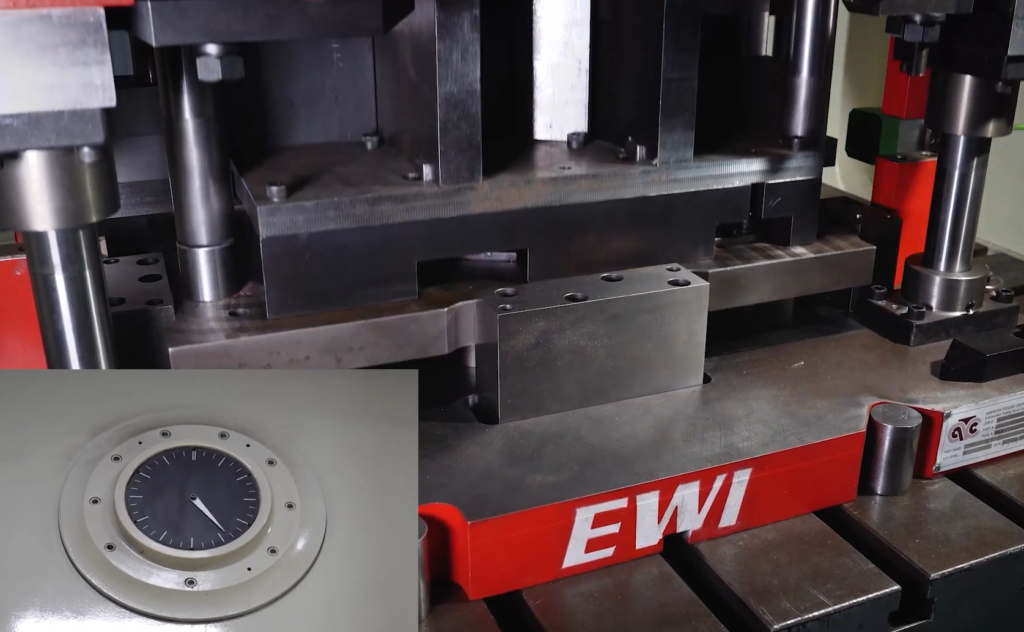

Springback challenges include difficulties predicting, controlling, and then compensating in the design and production phases. Therefore, a reliable springback prediction method is important to reduce downtime and increase efficiency as the part reaches the production stage. EWI has developed a new methodology to predict springback more accurately than previously. This method includes cyclic tension compression testing to create a material card that is suitable for predicting springback and experimental testing with a S-Rail die with real-time springback measurements to validate the material card.

Check out the video to learn more!

To learn more about this methodology, contact Laura Zoller ([email protected]) or Amir Asgharzadeh ([email protected]).