Microjoining encompasses techniques including welding, brazing, soldering, and adhesive bonding. Typically, the technology involves materials with thicknesses less than 0.5 mm. Micro-welding techniques can be applied to join both similar and dissimilar materials combinations. Here are some key applications of microjoining today:

- Power electronics for electric vehicles (EVs). The integration of small-scale components, such as chips, transistors, resistors, capacitors, and inductors, is a critical requirement for EV production. Micro-scale joining techniques can address the issues and enable further development of compact power electronics systems for EVs.

- Medical technologies. With biomedical and electronic devices now smaller and more intricate than ever before, the task of joining materials for these devices is more complex. To meet the demands of this rapidly evolving landscape, specialized joining processes are necessitated.

- Energy storage systems. The integration of batteries and interconnects at a small scale is essential for the advancement of energy storage systems. Successful assembly requires precise and robust joining techniques to ensure optimal performance, safety, and longevity.

For over 30 years, EWI has been developing and applying microjoining technologies to individual customer applications. Our systems include ultrasonic and thermosonic bonders, micro-TIG welders, precision resistance welders, ultrasonic welders, resistance reflow soldering and controlled-atmosphere furnaces. Our capabilities are described below:

Pulsed Arc Welding

Pulsed arc welding, a contactless process, involves striking an electrical arc between an electrode and the target component that produces a concentrated and high-energy density, leading to elevated local temperatures suitable for welding purposes. A precise power supply connected to a retracting welding electrode generates a brief but intense burst of energy. This technique welds metals with minimal heating of the component and is unaffected by electrical conductivity and optical reflectivity.

Pulsed arc welding can be used to join battery materials in pack assemblies. The technique is also suitable for welding very thin sheets as well as magnet wire for higher temperature coils and other wire-based applications. The ability to achieve precise and controlled welds while minimizing heat input makes pulsed arc welding an advantageous choice in these contexts.

Micro-resistance Welding

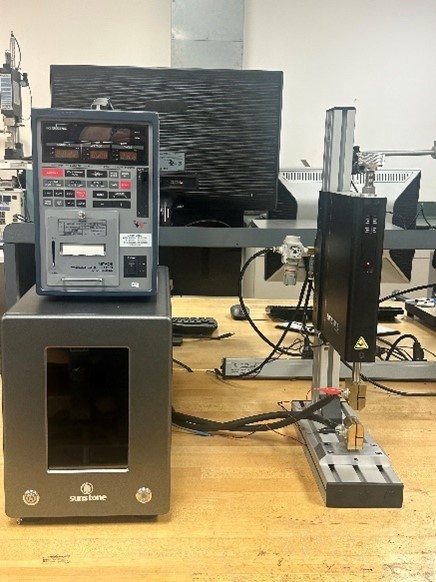

Micro-resistance welding is also appropriate for joining small components with high precision. The technique applies electric current and pressure to create a localized heat zone that fuses the materials together. The two materials to be joined are placed in contact, usually clamped with the welding electrodes themselves under a pre-defined force. An electric current is passed through the workpieces, generating resistance-based heating. The combination of heat and pressure creates the bond. Bonding may be either in the solid state (caused by deformation of materials) or from the creation of a fused (melted) nugget. A typical small-scale resistance welding system is shown in Figure 1.

Micro-resistance welding provides precise and controlled heat input. The heat-affected zone is localized and minimal which helps prevent damage to nearby sensitive materials. This level of control is crucial in microjoining applications, where even slight temperature variations can have significant impacts. The associated limited temperature fields are also critical for minimizing distortion associated with welding.

Today’s micro-resistance welding systems offer pulse shaping and on-board statistical control capabilities. The former can be effective for challenging resistance welding applications. The latter is a core feature for ongoing quality control strategies, facilitating consistent product performance in high-volume applications.

Micro-resistance welding, useful for both similar and dissimilar material combinations, has been applied across the electronics, medical devices, automotive, aerospace industries. Common applications include the assembly of miniature sensors, micro-connectors, fine wires, micro-electronics, and medical implants.

Percussion Welding

Percussion welding is a unique resistance-based process in which expulsion of metal at the contact surfaces of the opposing workpieces creates residual liquid films that are joined when subsequently pressed together. Percussion action from the implied expulsion event may be caused by using an ignitor tip on one of the components or by rapidly bringing the workpieces together under an applied voltage potential. In either case, once percussion occurs there is an established arc that rapidly expands radially across the workpiece interfaces under the influence of the magnetic field associated with the secondary winding. This expanding arc melts a small layer on each workpiece. The pieces are rapidly brought together, and bonding occurs. Since percussion welding occurs in micro-seconds, the consolidated parts undergo rapid solidification, allowing joining of difficult to bond and dissimilar materials.

Typical percussion welding equipment (shown in Figure 2) most commonly employs capacitors to supply the energy to create and sustain the arc through the process. However, the use of half-cycle alternating power is also used. In fact, the technology is possible with any source with sufficient voltage to cause percussive action within the micro-second time period. Of note, percussion welding is typically done under relatively low forces compared to other resistance welding processes. Here, the force is only required to accelerate the parts after arc initiation, as well as retain the workpiece after contact allowing rapid solidification.

Percussion welding applications include tab attachments in batteries, filament joining to assembly of dental drills, and applying electrical contacts. Percussion welding can be effectively applied to components as small as tens of microns in diameter to those in excess of tens of millimeters. It is used with a wide range of materials (aluminum, copper, nickel alloys, Nitinol, refractory metals), as well as dissimilar combinations.

Ultrasonic Welding

Ultrasonic welding offers numerous advantages in terms of speed, precision, and effectiveness. It involves the application of high-frequency ultrasonic vibrations to create frictional heat at the interface between the components to be joined. In this process, the ultrasonic vibrations and heat soften the materials, which then deforms and shears local surface asperities, disperses interface contaminants, brings metal-to-metal contact, and bonds the surfaces together under pressure, to form a strong bond.

In small-scale devices (e.g., electronic components, microelectromechanical systems, medical devices), ultrasonic welding offers several benefits. First, as a solid-state welding process, it generates heat lower than the melting point of the metal which reduces the occurance of defects. The process does not require the use of additional materials like adhesives or solder, reducing the risk of contamination or the need for extra processing steps. This makes it particularly suitable for applications where cleanliness and minimal residue are critical.

Second, ultrasonic welding is fast and efficient, often achieving joining within fraction of a second. This rapid operation is optimal for high-volume production scenarios where time is of the essence. Third, the precise control of the ultrasonic vibrations allows for selective welding of specific areas or delicate components without causing damage to surrounding materials. The localized nature of ultrasonic welding makes it ideal for joining small-scale devices with intricate geometries or tight tolerances. As a solid-state process, it enables the bonding of dissimilar metals, such as aluminum, copper, etc., which may have different melting points or thermal properties. And finally, the process can be easily automated, ensuring consistency and repeatability in production, while its energy efficiency and low operating costs make it an economical choice.

Ultrasonic soldering is a variant of traditional iron soldering in which the ultrasonic vibration from the soldering iron produces cavitation bubbles in the liquid solder. When the bubbles collapse, the mechanical motion abrasively removes the surface oxides from the metal to be soldered. Once this occurs, the liquid solder can bond to the metal substrate. In both cases, the soldering iron tips are heated and keep the solder liquid or molten on the tip. Ultrasonic soldering can be used for joining dissimilar materials such as metals, ceramics, glass, etc. However, all solders can be used with ultrasonic soldering, including lead-free and zinc-based solders.

EWI can help you develop and implement innovative, microjoining processes tailored to your needs, as well as assist with material selection, feasibility trials, process optimization, cost analysis, and technology transfer. For more details, contact [email protected].