Common aerospace materials such as high-nickel alloys (such as René 80) or high-strength aluminum alloys (6000 and 7000 series) are not currently manufactured using additive manufacturing (AM) due to hot cracking. As part of a $5M Department of Energy program, EWI, GE Research, and the University of South Carolina developed a model to predict and avoid hot cracking in René 80. Using additive manufacturing for high performance metal alloys enables design flexibility and the introduction of previously unbuildable parts.

Our probabilistic crack formation model is an ICME based Process->Thermal->Structure model. The steps in this model is described below:

- Process > Thermals: Process parameters and part geometry are used to predict the thermal history experienced by the René 80. This is done using a multi-source Rosenthal model. Rosenthal models are one example of computationally efficient analytic methods EWI often uses for thermal history prediction. In this case, we calibrate the model using in-situ thermal sensing.

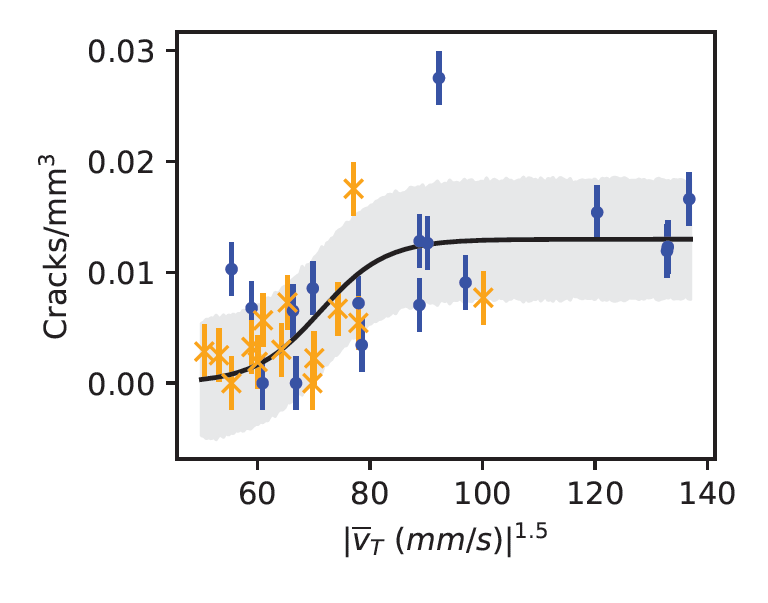

- Thermal > Structure: A hot cracking criteria is used to relate the predicted thermal histories to crack formation. In this case, we use a simplified version of the physics based RDG crack formation criteria. This model considers the fluid flow between dendrite arms during solidification.

The Process > Thermal > Structure model allows crack formation predictions to be made in seconds and gave consistently good results across multiple builds. Further, the model can be used in a feedback loop to select process parameters, modify design, and modify build strategy to minimize or eliminates cracking.

This specific approach was developed for René 80 but is applicable for other hot-cracking prone alloys.

For a full explanation of the development of this model, you can view our recently published paper in ADDITIVE MANUFACTURING, Physics-based Crack Formation Model for René 80 in laser Blown Direceted Energy Deposition: Theory and Experiment, by filling out the form below:

To discuss this work and how it might be applicable for your application, contact Alex Kitt at [email protected] or Matt Dodds at [email protected].

This work was supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) under the Advanced Manufacturing Office Award Number DE-EE0009118