Harnessing the Power of Finite Element Analysis

Part 6: Analysis of Non-Linear Dynamic Processes

By Amin Moghaddas

A non-linear dynamic process is one in which the system’s output is not directly proportional to its input, and small changes in one parameter can lead to large, unpredictable changes in the outcome. This non-linearity can arise from various factors, such as material behavior, contact interactions, and time-dependent factors. In manufacturing, non-linear dynamic processes can present significant challenges but also offer opportunities for optimization through advanced simulation tools like Finite Element Analysis (FEA).

Several industries deal with non-linear dynamic processes where traditional linear models fail to predict the system’s behavior accurately. For example, in the automotive and aerospace sectors, the design of crashworthy structures and the analysis of high-speed impacts require non-linear dynamic modeling to account for parameters such as material deformation. Similarly, machining operations like drilling and milling involve highly dynamic and non-linear forces, temperatures, and material deformations due to the complex interactions between cutting tools and materials. In the energy sector, modeling the behavior of offshore structures under wave and wind loads involves complex non-linear interactions that are critical for ensuring stability and durability.

FEA offers a powerful approach for simulating non-linear dynamic processes by breaking down complex systems into smaller, more manageable elements. It models material behaviors, dynamic forces, and temperature gradients over time, allowing for reasonably accurate predictions and optimizations.

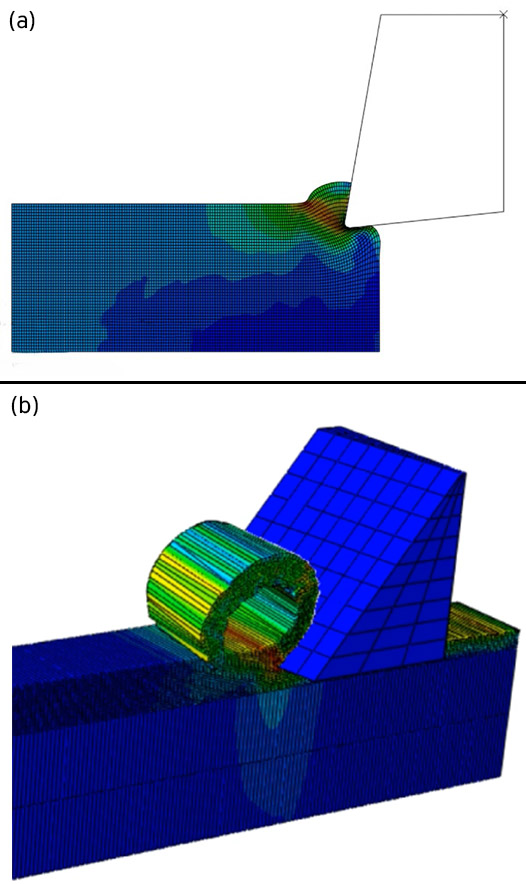

Figure 1 shows an example of FE modeling of an orthogonal cutting process. This process can be modeled in either 2D or 3D. The developed model can simulate the tool-material interaction and predict tool wear. It also helps optimize cutting parameters for improved efficiency. These simulations help to understand how dynamic forces and non-linear material behaviors influence the machining process, providing a comprehensive view of how changes in process parameters can impact performance.

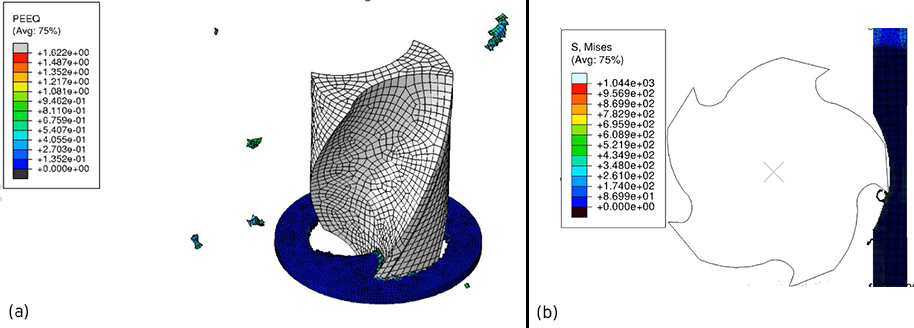

Machining processes such as milling and drilling, which involve the penetration of a rotating tool into a workpiece, are inherently non-linear as well. As shown in Figure 2, FEA can be used to simulate the dynamics of these processes, including chip formation and force interactions, optimizing tool design and machining parameters, ultimately enhancing machining performance.

Are you facing challenges with non-linear dynamic processes? Let’s discuss how FEA can optimize your system—contact Amin Moghaddas to explore solutions and learn more.

Read other articles in this series:

- Part 1: Introducing Finite Element Analysis

- Part 2: Harnessing the Power of FEA: Structural Analysis

- Part 3: Harnessing the Power of FEA: Vibrational Analysis

- Part 4: Harnessing the Power of FEA: Heat Transfer Analysis

- Part 5: Harnessing the Power of FEA: Hydrogen Diffusion Challenges in Pipelines

Amin Moghaddas is an Applications Engineer in the EWI resistance and solid-state group with more than 15 years of expertise in Finite Element Analysis (FEA). His primary focus is computational modeling of thermal processes, specializing in predicting temperature profile, residual stress, and distortion. Amin also has deep expertise in vibration analysis, designing and fabricating tooling for ultrasonic systems. Additionally, he is highly skilled in the structural analysis of components, including both static and dynamic simulations.