Ultrasonic Processes

Apply the power of ultrasonics to welding, joining and more.

Ultrasonic technology offers a high-power tool for a broad range of manufacturing applications.

For more than three decades, EWI has been a pioneer in developing ultrasonic technology for joining solutions. Our applied R&D program helps manufacturers harness the unique qualities of ultrasonics to successfully join hard-to-weld metals, dissimilar materials, and micro-components.

At EWI, we apply our expertise in high-power ultrasonic technology to applications beyond ultrasonic welding, such as cutting, surface engineering, package sealing, additive manufacturing, powder compaction, and wire drawing. We enable manufacturers to use ultrasonic-based processes to help them:

- Develop welding processes for new products and materials

- Optimize welding processes to reduce scrap, increase tool life, and reduce cycle time

- Improve material properties such as hardness, surface finish, and fatigue life through ultrasonic processing

- Design, fabricate, and test high-power ultrasonic (HPU) systems customized to their application

Ultrasonic Welding & Process Development

Developing new technologies or modifying existing equipment starts with careful process development. The EWI ultrasonics team uses a scientific approach to achieve results:

- Process development

- Design of experiments (DOE)

- Testing and evaluation of high-powered ultrasound (HPU) systems

- Ultrasonic weld testing (e.g., post-weld joint integrity)

- Ultrasonic tool design

EWI’s ultrasonics team has led the industry in ultrasonic research and published foundational works in the field. With our deep understanding of ultrasonic technology and our cross-departmental strengths, we achieve our clients’ production or design goals in innovative and unexpected ways.

Commercial Applications

EWI’s ultrasonics technology group has had numerous successes developing, patenting, and commercializing new products. Two of these innovations have since spun out as independent, affiliated enterprises:

Ultrasonic Package Sealing

UltraThinSeal is a pioneer of ultrasonic packaging technology. The company offers a unique system developed by EWI engineers. Using the basic mechanics of ultrasonic welding in a patented system, the UltraThinSeal process is able to join extremely delicate materials such as snack package films to create strong seals as small as 1mm. Compared to traditional thermal sealing, this system produces better seal quality and far less waste, and it’s viable for biodegradable materials and PLA.

Ultrasonic Additive Manufacturing

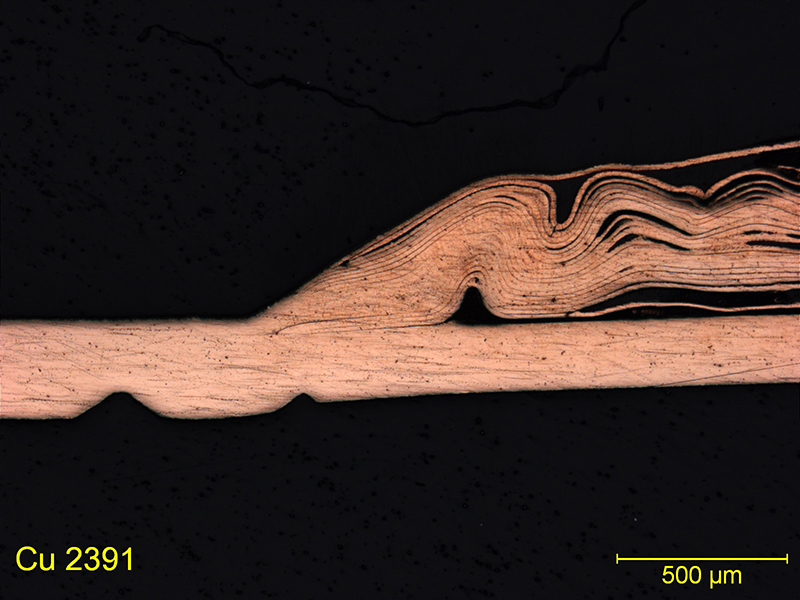

Fabrisonic LLC provides 3D metal printing services using ultrasonic additive manufacturing (UAM) technology, invented by EWI. UAM is one-of-a-kind hybrid technology that combines a unique room-temperature metal deposition process with the ease of traditional CNC milling. Solid metal objects are built up to a net three-dimensional shape through a succession of ultrasonically welded metal tapes. CNC contour milling is used between tape layers to achieve required tolerances and surface finish. By leveraging advantages of additive and subtractive fabrication approaches, the Fabrisonic system can build complex 3D with high dimensional accuracy and smooth surfaces, including objects with complex internal passageways.

Identify.

Develop.

Implement.

WE MANUFACTURE INNOVATION.

That’s how we surmount unique challenges with customized ultrasonic solutions to further the success of our partners. Our ultrasonics team is ready to help your organization.

Applied Ultrasonic Expertise

Ultrasonic technology might offer a solution to your manufacturing challenge. To explore the possibilities with our ultrasonics specialists, contact us today.

Technical Expertise

EWI’s range of ultrasonic welding and process expertise includes the following.

- High-powered ultrasound (HPU) system design

- Plastics joining

- Microjoining

- Ultrasonic metal welding

- Additive manufacturing

- Ultrasonically assisted forming, wire drawing, soldering, and brazing

- Friction reduction

- Cleaning and defoaming

- Food processing and package sealing

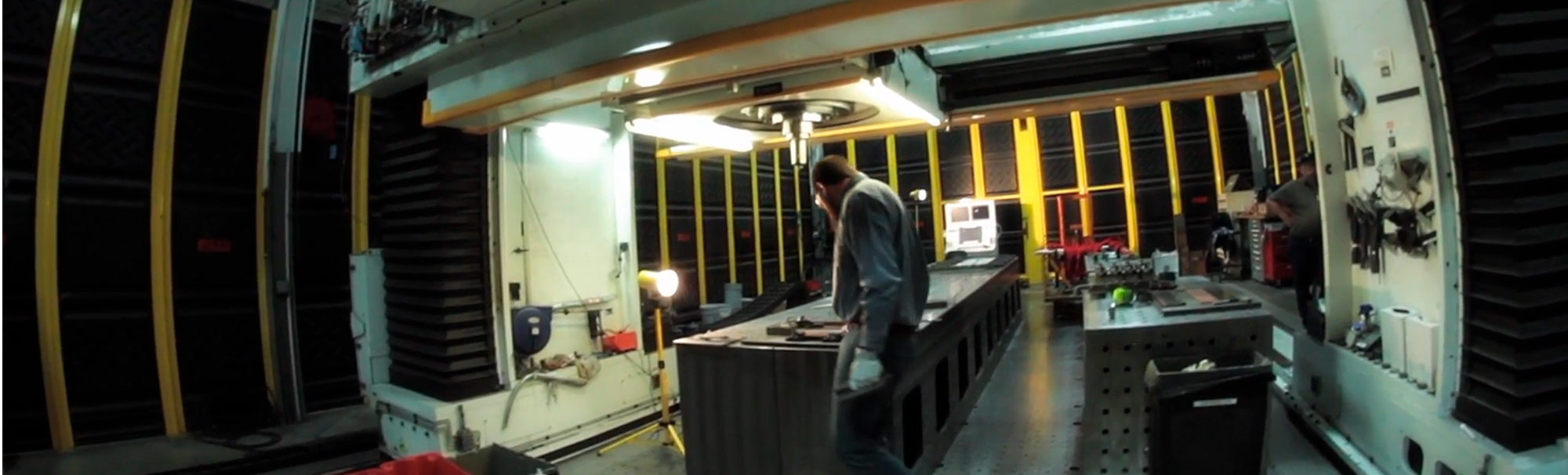

Equipment & Lab Resources

Our experts are well-equipped with the resources they need to think big with ultrasonics.

Ultrasonic metal welding systems (lateral drive,wedge-reed, torsion, seam)

- Frequencies from 15 to 60 kHz

- Power from 500 to 10,000 W

Ultrasonic plastic welding systems

- Frequencies from 15 to 60 kHz

- Power from 500 W to 6 kW

Ultrasonic package sealing equipment

- Vertical Form Fill Seal (VFFS) demonstration unit

- Benchtop sealing equipment for feasibility

- Dual-face rotary package welding system

Lead-free ultrasonic soldering and brazing equipment

Per-unit (PU) system testing and evaluation equipment

- 1D and 2D laser virometer

- Impedance analyzer

- Spectrum analyzer

- High-power motor-generator transducer test bench

- Infrared thermography for thermal profiling

High-powered ultrasound (HPU) design, modeling and testing equipment

- Creo Parametric

- SolidWorks

- Abaqus

- Ansys

- Piezotran