“Measure twice, cut once.” If you’re like me, this is something I never forget to do… except when I forget to do it and end up making my 4th trip back to the Home Depot dropping another $45.

What’s my point? The EWI modeling group is the equivalent of a really, really good tape measure.

I sat down and spoke with Yu-Ping Yang who patiently explained to me modeling at EWI. He began by saying modeling is a way to save money on a project (clearly he remembered he was talking to an accountant). If you have a big dollar structure you’re building, it’s more cost effective to model how that part will perform before making it.

That is, “model twice, build once.”

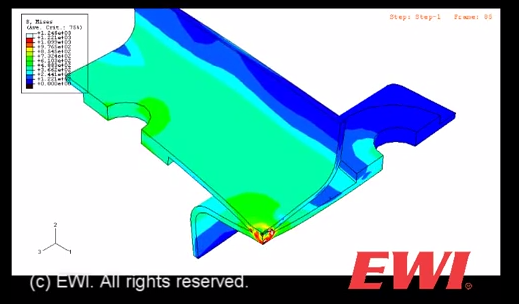

Our modelers are also able to optimize a high volume process. If you can get the same part performance using less expensive materials or materials that allow for more efficient manufacturing (> parts per hour) that is a huge win for our members. Now those are a few reasons to use a modeler… not The EWI modeling group. Our modelers have a tremendous breadth of expertise in welding, forming, and all types of joining, including being able to model high temperatures. They have developed models around predicting complex distortion and tolerance outcomes; heat transfer; microstructure and hardness prediction; crash simulation; and cracking and stress. And they have expertise in many common (amongst the modeler types) software tools like Abaqus, D-Form, LS Dyna, MSC Software, and Hyperworks. EWI modelers are able to use our own HPC (“high performance cluster”), multiple modeling specific server platforms, numerous virtual servers, as well as having access to the Ohio SuperComputer center. Best of all, EWI modelers are integrated within our project teams where it makes sense: as part of the design of experiment, design of part, or outcome modeling.

A successful modeling project can take many forms. One that narrows down process variables eliminating wasted effort and cost… One that identifies an outcome over time without having to wait… Or one that saves you from building a structure with less than ideal parameters. Any one of these reasons will save you much more than a trip to Home Depot to remedy.

Have a modeling question or challenge, please feel free to contact Yu-Ping Yang at EWI.