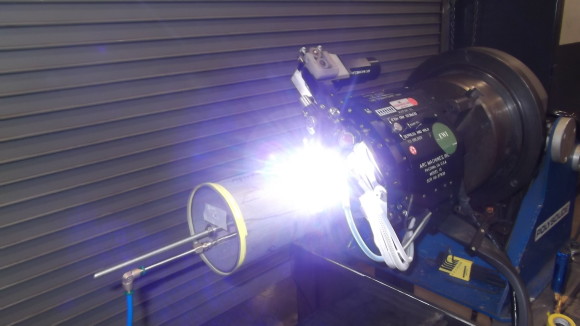

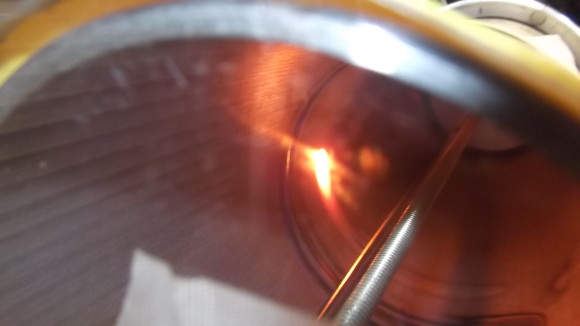

EWI is capable of performing orbital welding, a specialized welding process whereby the arc is rotated mechanically around a static workpiece such as a pipe in a continuous process. The technique was developed over 50 years ago, and with today’s modern technology is a sound, robust, and easy-to-use method of joining cylindrical components. These components can be pipes or tubes with diameters as small as 1/16 in. and walls as thin as 0.010 in., or large-diameter cylindrical parts (14 feet and greater) with wall thicknesses of up to 12 in. Parts can be made of many material types including carbon and alloy steels, stainless steels, nickel based alloys, titanium, and even some aluminum alloys. A good rule of thumb is that if it can be successfully welded manually, it can likely be welded using orbital equipment. The most commonly used processes are gas tungsten arc welding (GTAW), pulsed gas metal arc welding (P-GMAW), and flux cored arc welding (FCAW), but other processes can be utilized as well.

Orbital welding is often considered a slow, costly process with low production-rates requiring expensive equipment and highly trained equipment operators. While that’s true to a degree, significant benefits and cost savings can be realized when using this process for fabrication of both simple and complex systems.

A sub-category of orbital welding is narrow-groove orbital welding (NG-Orbital Welding). In this process variation, the welding head and torch are designed for use with narrow weld joints with restricted access. This can have a significant impact when welding large-diameter heavy-wall components. A normal groove for a pipe weld ranges from 30 to 90 degrees, depending on the process. A narrow-groove process requires only a 2 to 5 degree bevel. This represents a significant reduction in weld volume which translates to higher productivity and often a reduction in welding-induced distortion.

Other benefits of orbital welding are high weld-quality levels and excellent repeatability. In addition, good welders can be quickly trained on the use of this equipment to produce high-quality welds. And overall, it is a cleaner process that is generally conducted in a more operator-friendly environment.

It is highly unlikely that orbital welding will ever replace manual welding for normal fabrication because it is not suited for every application. But if you look at the numbers for your fabrication processes, orbital welding may save you time and money and decrease the reject rate of your fabrications.

EWI can help you determine if orbital welding is a good fit for your business. To learn more, contact Steve Manring at 614.688.5196 or at [email protected]