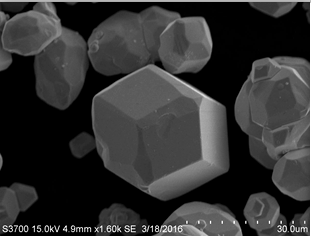

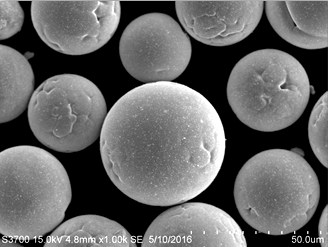

Metal additive manufacturing (AM) processes allow the creation of complex, cutting-edge, and never-before-seen designs using a wide range of alloys. With an array of readily available AM technologies at their disposal, manufacturers are now focused on material development and processing to ensure the quality of their built components. Characterization of the powders used in many AM processes is a critical part of this effort, and includes analysis of particle density, flow, morphology, size, and thermal properties. Powders that are found to be unsuitable for a given AM process and application can then be processed to improve characteristics such as flowability, density, and purity.

Brendan Lewis, EWI’s AM Technician at Buffalo Manufacturing Works, has written The Importance of Powder Characterization in Metal Additive Manufacturing to discuss powder characterization techniques, the influence of powder characteristics on process parameters, and the ways in which powders can be processed to improve their performance.

If you’d like to learn more about how EWI’s experts can help you improve quality and performance using AM technologies, contact us.