Ultrasonic metal foil additive manufacturing is a technology that was pioneered by Fabrisonic, an affiliate of EWI. It uses ultrasonic welding to build up metal parts layer by layer – a low-temperature, solid-state process that can produce 3D-printed parts as large as 6’ x 6’ square.

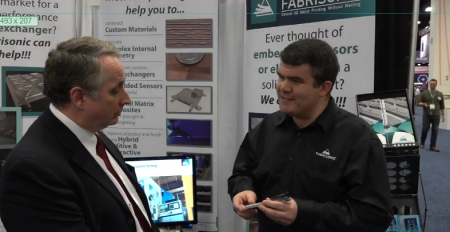

Recently, Fabrisonic President Mark Norfolk gave a terrific explanation of ultrasonic additive manufacturing (UAM) and its advantages in an interview at the RAPID + TCT 3D printing event in Fort Worth, Texas. A short video of his conversation with James Anderton can be viewed on engineering.com.

Watch the interview to learn all about the UAM process and its advantages.