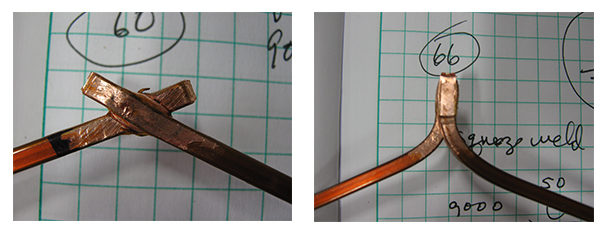

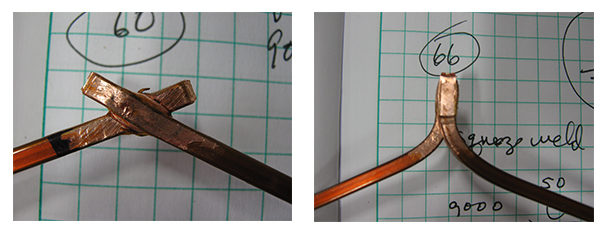

Stator windings in traction motors for electric vehicles are created by joining multiple short copper wire sections. Current joining approaches for these multiple copper wire sections lack the productivity for high volume manufacturing, require an increased amount of copper for assembly, and risk reduced joint strength due to softened copper from extended thermal cycles.

In his new paper, Joining Challenges in the Manufacture of Motors for Electric Vehicles – Stator Winding Assemblies, EWI Technology Fellow Jerry Gould discusses two emerging technologies for

To learn how these emerging technologies can increase productivity, reduce thermal cycles, and increase strength in joining for stator windings, download the paper here.

To learn more about EWI’s work in resistance welding for vehicle electrification, please contact Jerry Gould at [email protected].