Developing reliable joining technologies for products using flexible hybrid electronics (FHEs) and 3D-printed electronics is mission critical for consumer, medical device, and military electronics applications.

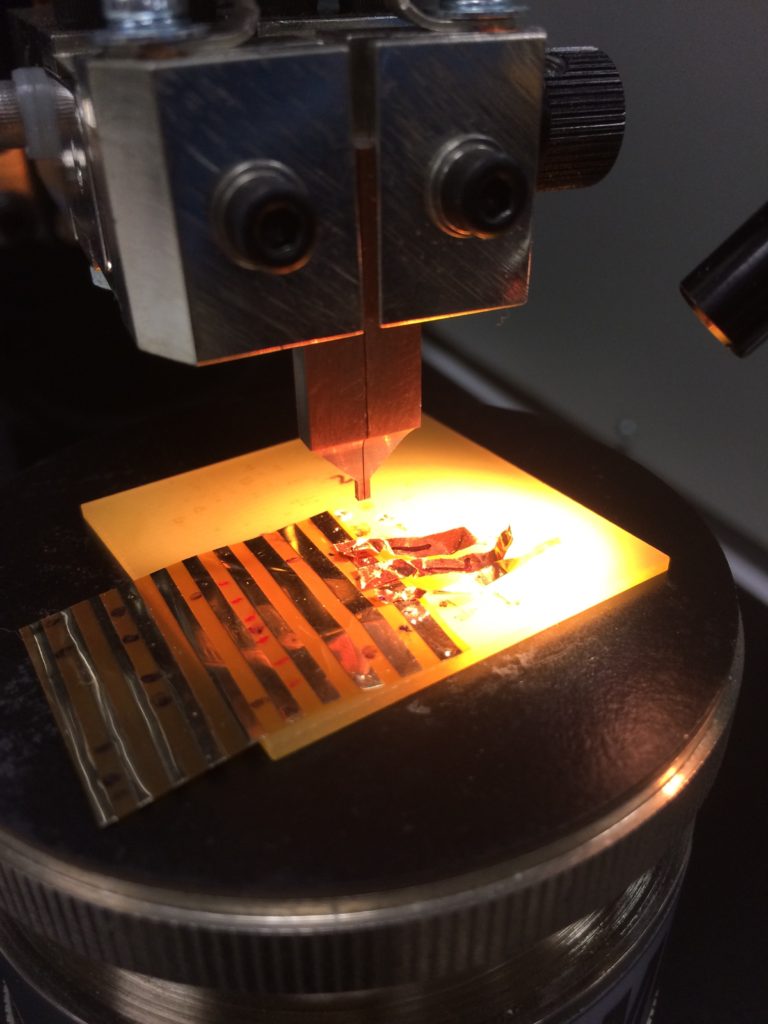

While soldering is currently used in prototyping for these applications, it may not be viable for high-volume manufacturing – due to limitations of speed, joint size, reliability, and strength. EWI recently completed a study evaluating two promising welding processes that have been used in mass production for decades – parallel gap and ultrasonic welding – specifically for joining of FHEs and 3D-printed electronics.

This work is presented in Better Techniques for Joining FHE and 3D-printed Electronics, a new paper written by EWI Senior Engineer Tim Frech.

For more information about this project, contact Tim Frech at [email protected].