The first-time quality of stampings with reduced scrap rates is a primary goal of the metal stamping industry. However, emerging high-strength steels significantly increase the variations of the incoming coil properties and die friction.

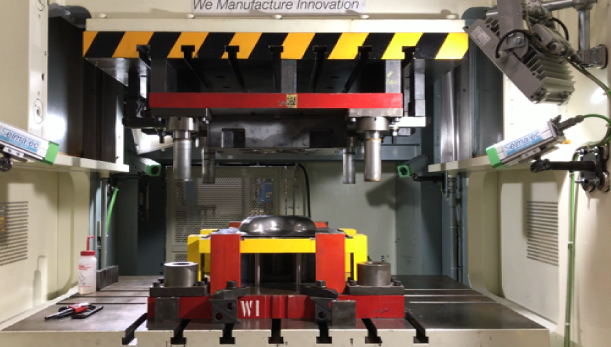

To address this challenging issue, the EWI Forming Center has led the Intelligent Servo-Controlled Forming Project with 12 industry partners for the past two years. As part of this project, both nondestructive evaluation (NDE) and visual monitoring methods were used to obtain a variation of the incoming material properties and forming process conditions.

These real-time measured data were used for the machine learning algorithm to adjust the forming process parameters. A control algorithm was developed to estimate results and make recommendations for forming process changes by interacting with engineers. Final validation testing of multiple grades of steels and batch materials successfully demonstrated the successful application of the control algorithm in sheet metal forming.

Currently, EWI is working with industry partners to commercialize the developed control algorithm for the production application. Updates on this project will be available later this year.

If you are interested in learning more about EWI’s experience and capabilities in this subject, please contact Hyunok Kim ([email protected]) or Doug Myers ([email protected]).