Springback is a critical challenge of forming and welding sheet metal parts for manufacturing applications in the aerospace, automotive, energy, electronics, and heavy manufacturing industries. Springback measurements can vary with material properties, stress-strain variables, part geometry, friction between forming tools, etc. It is difficult to eliminate springback during cold forming processes, but it can be controlled by compensating for the resulting dimensional change.

There are numerous considerations for welding formed parts where springback is present. For example, the clamping forces in tooling must be adequately addressed to ensure optimum joint fit-up for welding. Reliable prediction and practical compensation of springback forces are imperative to maximized weld quality and stabilize fabrication processes.

The automotive industry is increasingly adopting advanced high-strength steel (AHSS) and high-strength aluminum alloys for the automotive body structure. Newly emerging generation-3 AHSS and high-strength aluminum alloys are starting to be used in production and stampers addressed increased challenges with the increased springback of these emerging materials.

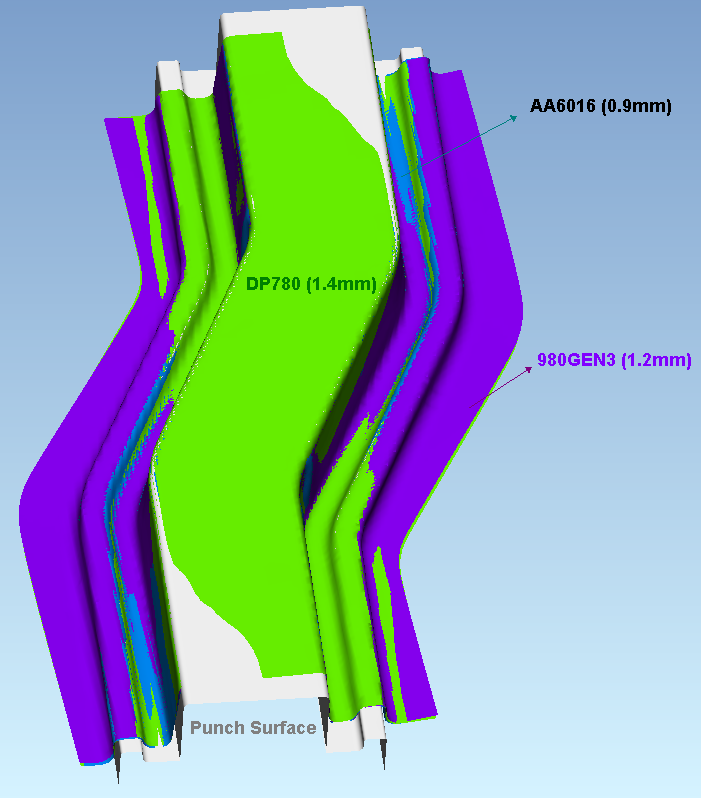

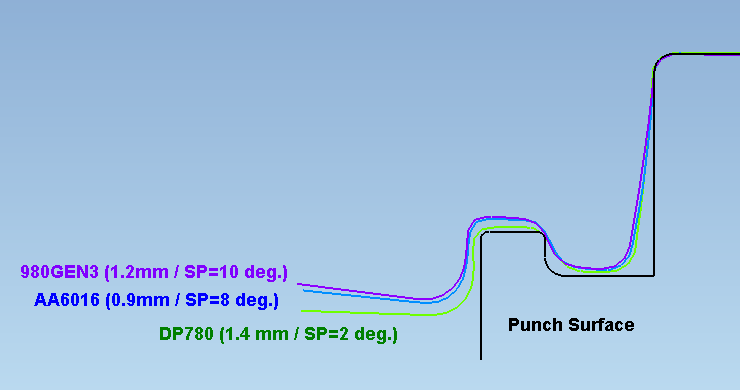

Comparison of springback of three selected materials in a S-rail part

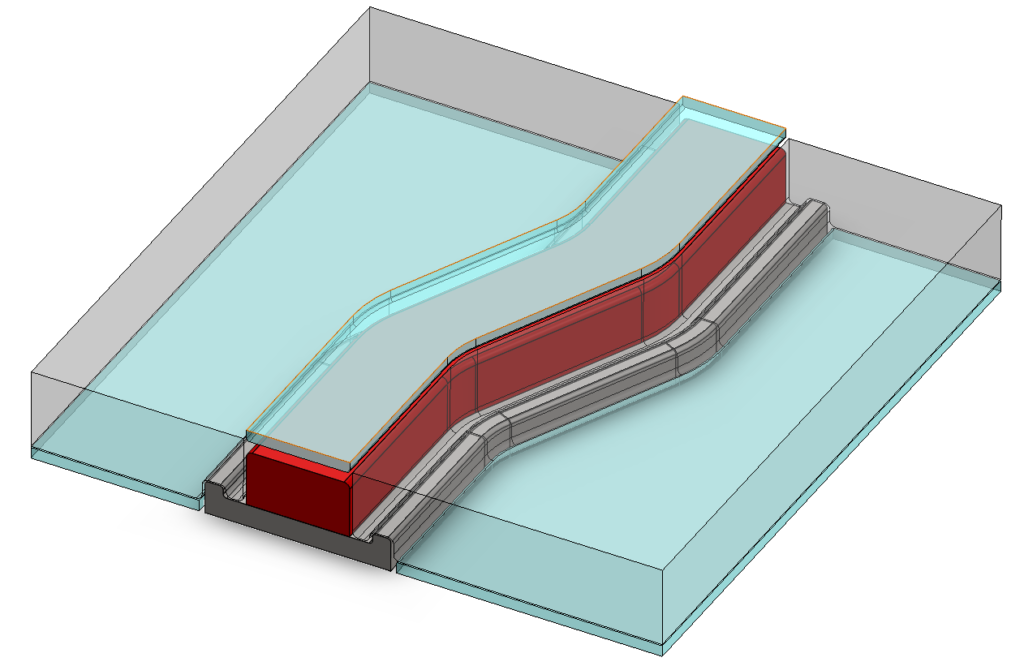

EWI forming team recently developed a new springback test tooling to evaluate and control the springback of selected aluminum 6xxx alloys and GEN3 steel using an S-rail part and a 300-ton servo press. Preliminary simulation results showed springback of GEN980 steel and AA6016 to be 5x and 4x larger, respectively, than a conventional AHSS, dual-phase 780 material (see figures above). When the tooling is completely fabricated in early spring, EWI will investigate the effects of the following key variables on springback for selected GEN3 and aluminum alloys.

- Material flow curves, kinematic hardening, and yield function models

- Variation of the incoming material properties from multiple batch materials

- Stake-beads on the tool

- Servo press slide and binder force profiles

EWI also plans to use a real-time visual monitoring system to monitor the part springback. The monitoring system is very practical and useful to measure springback in a production environment.

For more information, please contact [email protected].