The newest generation of a product is typically lighter, smaller, and more powerful than its predecessor. For these products to be as successful as the previous iterations, they must be manufactured in an economical and reliable manner. In many cases, this requires going back to the drawing board to select materials, finalize a design, and choose joining processes – daunting tasks for a design engineer.

EWI has provided solutions for small-scale materials joining to many industry sectors, including medical and consumer products. These devices have included ingestibles, injectables, and sensors. Due to client confidentiality, EWI cannot share the details of these projects publicly. However, EWI has welded generic specimens to demonstrate our material science expertise and capabilities for developing welding processes for products with small parts.

film, both in ABS

Many new products have small plastic components that function as structural support, waterproof boundaries, and aesthetically pleasing external housings. These injection molded parts usually require a secondary joining process during final product assembly. Likewise, inside the plastic housing are circuit boards connected to sensors, batteries, antennas, speakers, and LEDs through very small metal interconnections. Examples include wireless earbuds, wearable health monitoring devices, and smart phones. The manufacturing processes for joining plastics and metals must have short cycle time, be repeatably reliable, and be economically attractive.

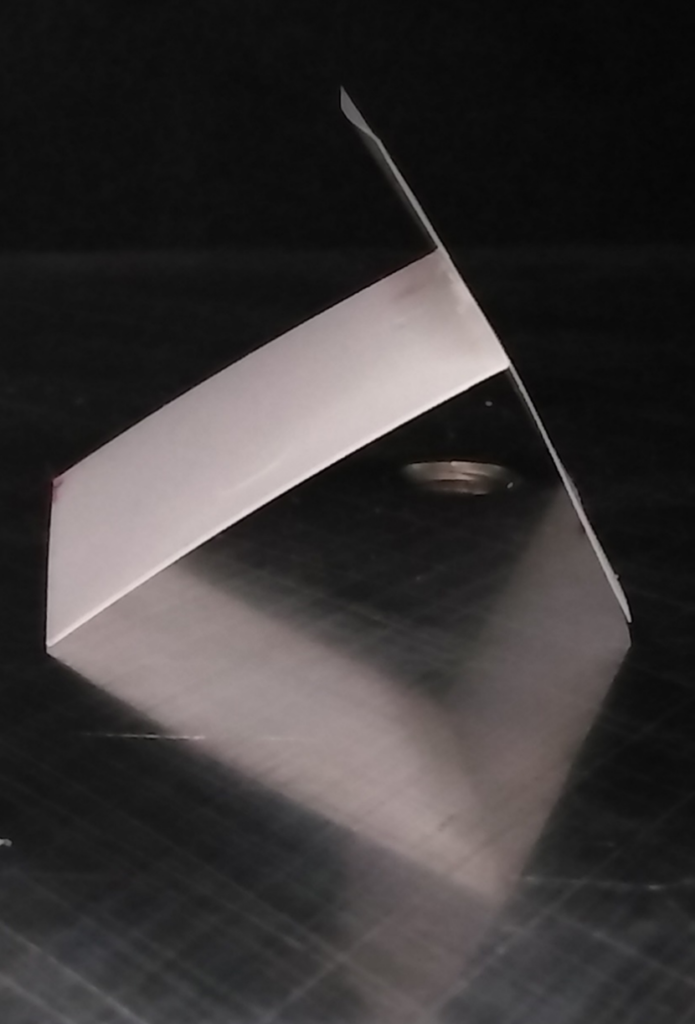

Recently, EWI demonstrated small-scale plastic ultrasonic welding by joining a one-inch-long T-joint of 0.003-inch-thick to 0.005-inch-thick film, in both acrylonitrile butadiene styrene (ABS) and polyoxymethylene (POM). This weld was made using a 35 kHz MS servo-controlled ultrasonic welder which provides the ability to have a slow weld speed and a sensitive trigger. For the initial welds, a trigger force of 15N, 0.2-mm weld collapse, and 0.3mm/sec weld speed was used (0.67-sec weld time). The first welds produced a tensile strength of 6.5N for ABS and 33.4N for POM. Further trials with varied process settings will be conducted and reported later.

This thin film bonding is useful in products that require film-to-frame or membrane-to-frame joining, like dialysis or fuel cell devices. Next, EWI plans to demonstrate laser welding of single polymer threads.

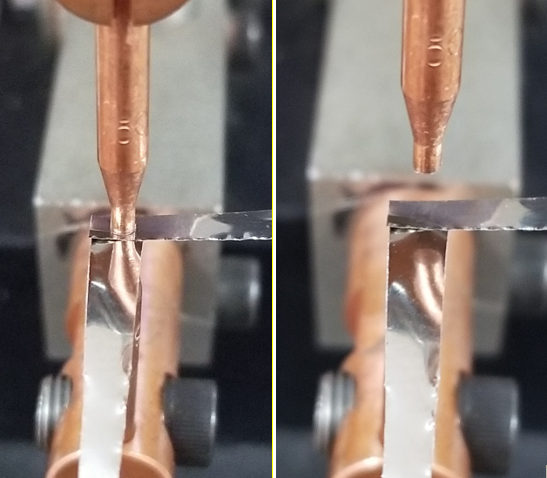

during welding (left) and after welding (right).

EWI has also demonstrated metallic microjoining by resistance spot welding layers of 0.0005-inch stainless steel foil. These foils are used as battery tabs and must maintain good electrical contact throughout their product’s life to continue to provide power. Next, EWI plans to demonstrate resistance and ultrasonic welding of 10-micron diameter copper wire. The wire will be welded to itself (as may be used in a medical device) or to a printed flexible electronic assembly.

Do you have an idea for a small product or a product with small parts but don’t know how to manufacture it? EWI can help you choose the best materials, perform feasibility welding trials on your parts, define your processing window, calculate manufacturing costs for your production scale, and transfer the joining technology to your manufacturing plant. Contact Senior Technology Leader Jeff Ellis at [email protected]