Produce Reliable Products with a Documentable Polymer Selection Process

Material selection is an important part of every design cycle because material failures eventually cause product failures. Of course, every company wants to avoid product failures in the marketplace. To do so, material properties as a function of their service life and surrounding environments must be considered. Rigorous material selection follows a process to incorporate these considerations and outputs traceable documentation that details the reasoning that supports the decisions.

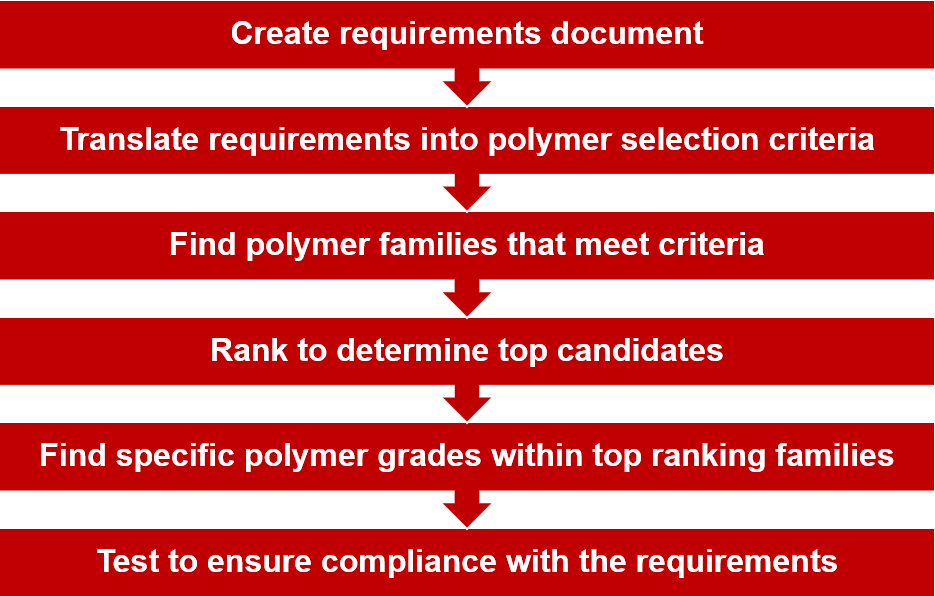

The process implements the following tasks to incorporate a systematic approach to material selection:

Drafting a Requirements Document

The requirements document includes the known conditions that the material will encounter during its lifecycle. For a polymer material, this includes — but is not limited to — resin at the material supplier, shipping to molder, molding conditions, shipping molded parts to assembler, assembly stresses, shipping product to customer, customer use, and disposal. Through its life, the polymer could encounter environments that are hot, cold, humid, dry, high stress, oxidative, and ultraviolet irradiative, as well as others. The material must continue to pass all the requirements through these environments to allow the product to function. The list below contains some of the conditions to consider when drafting the requirements document.

- Mechanical properties

- Thermal properties

- Chemical compatibility

- Aesthetics

- Processing

- Long term stability

- Barrier properties

- Price, availability, and global supply

Each requirement should have a pass/fail limit associated with it. An example is a ketchup bottle must survive a 20 lb. hand squeeze during use at typical indoor temperatures. This requirement includes both mechanical and thermal requirements. This quantifiable metric that can be translated into selection criteria in the next section.

Translating Material Selection Criteria

Once the document is finalized, then each of the requirements can be translated into a selection criterion for the material. For ketchup bottle example, depending on the design, it could translate to a Young’s modulus of at least 1 GPa, a flexural strength of at least 50 MPa, and an elongation at yield of at least 4% at a temperature range from 5 to 50°C. This translation is not trivial and requires a fundamental understanding of material science, but if done properly, it is highly valuable to mitigating risk of product failure.

The translated quantifiable metrics can be used for selection criteria. They are material properties that are typically listed on polymer datasheets and can be used to down-select material grades. Once all selection criteria have been translated from the requirements, then the initial selection of materials can commence.

Selecting a Polymer Family

There are too many specific polymer grades to search all of them for a product. Therefore, during the initial selection of materials, polymer families (e.g., PET versus PC) are compared against the selection criteria. The material properties that exceed the selection criteria metrics are scored high, while those that do not score low. The scores are summed in a table, and generic polymer grades that meet the most criteria are ranked highest. Many times, there is not a single material family that satisfies all the selection criteria. In these cases, weighting of the criteria is necessary. For example, the mechanical properties may be weighted higher than the aesthetic properties because the product must not break when squeezed, but being a certain color is only a nice to have. Weighted or not, the highest-ranking material families will be best suited to producing the lowest-risk product.

Finalizing a Specific Material Grade

During final material selection, the highest-ranking families from the previous task are used to inform specific grade selection. For example, if PET was found to be the highest-ranking family, then PET grades from different resin suppliers would be considered for use. Their technical datasheets are used to ensure that the specific grade meets the selection criteria. Just as in selecting a material family, a ranking table is populated and used to determine the best material for the product.

Many times, the technical datasheet does not have enough information to inform every one of the pass/fail criteria. In this case, it is important to test for the unknown values. For example, a proprietary chemical formulation (e.g., new flavored ketchup) will contact the material being selected, but there is no chemical resistance data for this binary interaction. It is important to understand the chemical effects the liquid has on the material. To gather data, an Environmental Stress Cracking (ESC) test could be performed to fill the void in the data. Tests should be run on the top material candidates to fill all data voids before finalizing a resin for production.

Conclusion

The material selection process described here has been used by many product design teams field robust products. The output of the process provides detailed documentation to why material decisions were made, which is valuable for future product design teams working on product upgrades, new products, or sourcing alternative materials due to supply chain issues. Investing in a rigorous material selection process pays for itself by creating referenceable selection documentation and producing reliable products.