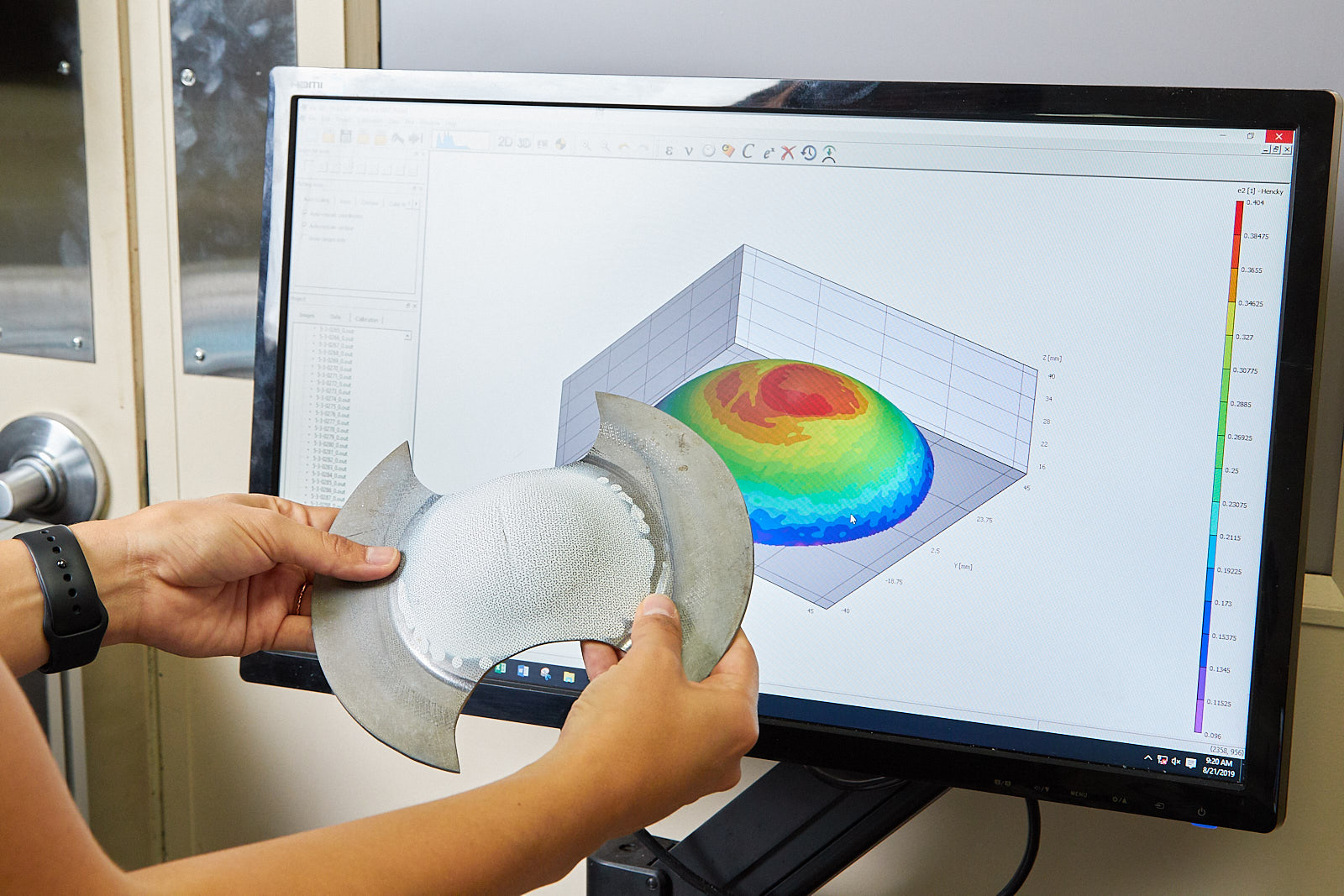

Bulge Test: A Valuable Tool for Material Formability Evaluation

Tensile testing over time is the first step in determining property variation for new material forming. However, industrial stamping processes often experience higher strain than what can be measured in a tensile test. Bulge testing can dramatically improve the accuracy of the yield surface of new materials. The EWI Forming Center recently developed the bulge […]

Read More

Did you miss EWI’s formability test methods webinar?

Updated Formability Test Methods, an EWI technical webinar, was presented by Engineering Group Leader Laura Zoller and Project Engineer Amir Asgharzadeh on May 3rd. If you were unable to attend, you can still view this recorded presentation – for free and on your own time – by completing the form below. Yes, I would like access […]

Read More

Webinar — Updated Formability Test Methods

Updated Formability Test Methods An EWI Webinar Wednesday, May 3, 2023 1:00-2:00 pm EST Please join EWI Forming Engineers Amir Asgharzadeh and Laura Zoller to learn about the latest material formability tests and why comprehensive testing is is crucial to fully understanding new and/or challenging materials for use in forming. The webinar will cover the […]

Read More

An Improved Method for Determining Flow Stress for Sheet Metal Forming Modeling

EWI has recently developed a new technique to obtain improved accuracy in material flow stress for modeling metal forming processes. The method uses the hydraulic bulge test (HBT) and digital image correlation (DIC) analysis and applies the plastic work equivalency principle to determine an optimal arc length for the for calculation of a biaxial flow […]

Read More

Evaluate the Formability of Your Material Today

EWI offers a comprehensive suite of material formability tests for sheet material including steel, aluminum, titanium, and nickel alloys. Our experienced engineers evaluate the results of these tests to provide recommendations on lubricants, coatings, and materials for your specific application. Learn more about our material testing capabilities. EWI’s Formability Testing Capabilities The EWI forming labs […]

Read More

Forming

The EWI Forming Center helps organizations evaluate new forming technology so they can fully harness it for their operations. Our advantage is twofold: We have the materials expertise and technology to test, refine, and innovate new solutions. Advanced forming capabilities in the EWI Forming Center are supported by the following: These resources enable our engineers to […]

Read More