At EWI, we’ve noticed that the global mindset toward inserting automation into the production line has shifted in a positive direction. Companies have realized that people really are the most important resource, and simply replacing them with robots is not the best approach. The greatest opportunities lie in the right mix of people and machines. Today, there is an increased interest in using automation to augment the current workforce, especially to relieve them of tedious, repetitive, or potentially dangerous tasks.

One such example is CNC machine tending, a task that requires little need for experience or on-the-job decisions but has traditionally been performed by highly skilled CNC machinists. Adding a robot to automatically load and unload parts can free up the machinist for more critical (and interesting) tasks like writing programs, performing changeovers, and training junior staff members.

At the other end of the spectrum, there is an increasing need for advanced automation systems to handle novel processes and new types of inspection, such as welding in a hazardous environment or in-processes monitoring of an additive manufacturing build.

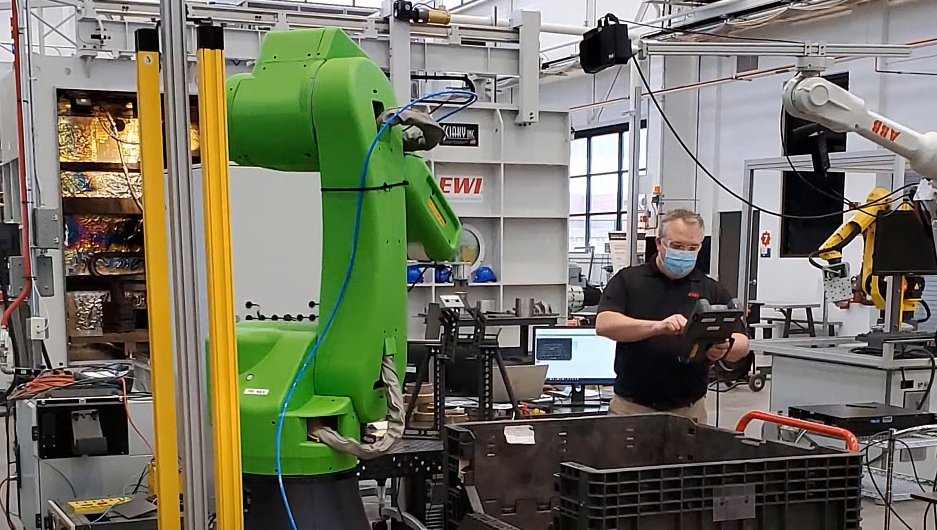

EWI has a long history of automation work, particularly related to welding processes. In the past, however, the technology was simply viewed as a tool that could be applied to enhance a project. The growing demand for automated solutions, combined with the rapid evolution in robot, sensor, and process technologies has given EWI the opportunity to re-evaluate this approach. As a result, we are rolling out a dedicated R&D program aimed towards custom automation solutions that solve difficult high-mix production and fabrication challenges.

EWI’s automation initiative revolves around four key technology pillars – 1) automated quality control and sensor technologies, 2) tele-manufacturing, 3) collaborative automation (cobot) platforms, and 4) automated path planning. Industrial training is a common thread throughout. The automation staff and labs at both EWI’s NY and OH facilities are being expanded, and new development projects are already underway with clients throughout the country.

EWI’s automation team is fully activated and ready to help your organization harness the power of advanced automation. From identifying the right automation opportunities, to developing and proving out applications, to mapping out a path to implementation on the factory floor, our team members can help at any point along your automation journey.

To find out how you can benefit from our automation services, contact Dan Vrana at [email protected].