EWI DeepTIG™, developed through the Navy ManTech Program in the 1990s, increases productivity during gas tungsten arc welding (GTAW) by enabling simplified joint preparations and reduced number of passes. It is classified by the American Welding Society as a penetration enhancing flux with many user benefits. GTAW welds made with EWI DeepTIG are typically produced in a single pass on square groove butt-joints with base material thickness up to 3/8-in thick.

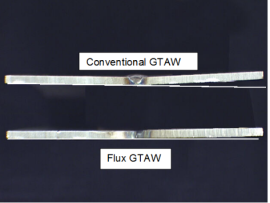

For some time, EWI DeepTIG has been available in specialized flux formulas for carbon steel, stainless steel, and nickel-based alloys. Now, a more user-friendly version of the product, EWI DeepTIG wire, is also available and can be used like any other welding filler metal. The advantage is that penetration can be increased 250%-300% compared to conventional welds made with solid wire.

EWI DeepTIG wire has been validated by work that EWI has performed for the National Shipbuilding Research Program (NSRP) to improve the productivity of pipe welding in U.S. shipyards. This work is discussed in a new paper by EWI Senior Engineer Nick Kapustka, Advancements in EWI DeepTIG™ for Higher Productivity GTAW.

Order or learn more about EWI DeepTIG products, by contacting [email protected].