Gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW) are both regularly used for welding aluminum. GTAW is a slow process when compared to GMAW and GMAW is typically used when extremely high weld quality (with respect to porosity) is not required. GMAW works well for welding aluminum in structural, automotive, or thick section multi-pass welding, but can reach a limit at over 40-inch/min travel speed.For welding thicker aluminum structures (0.25-inch or above) a higher productivity welding process may be desired.

Tandem-GMAW, which is traditionally applied to steel for higher productivity, can also successfully be applied to aluminum. Work has been performed at EWI to demonstrate fillet welds on 0.25-inch thick 6061 aluminum plates in t-joint and lap configurations. The electrodes used for these demonstrations were 3/64-inch diameter ER-5356 and the shielding gas was 100% Argon. Welding speeds of 60-inch/minute were achieved in both joint configurations. In both cases, the process was stable and minimal spatter was ejected from the weld pool. The stability of the process at 60-inch/min suggests that higher travel speeds could be possible.

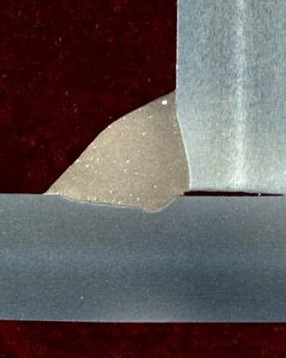

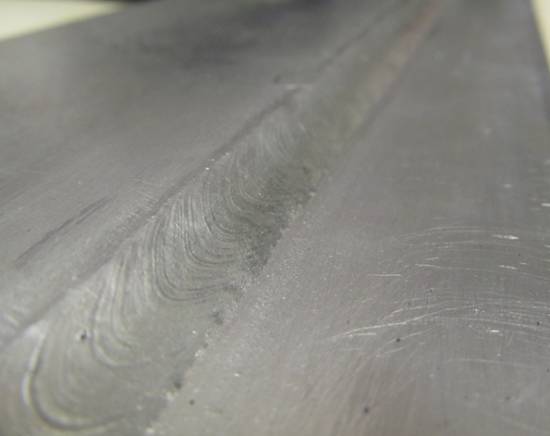

Figure 1 shows the fillet weld in the t-joint configuration. Note the consistency of the weld toes. Figure 2 shows a macro of the same weld; which indicates ample fusion at the weld root.

Figure 1. 0.25-inch fillet weld in t-joint at 60-inch/min travel speed

Figure 2. Macro of fillet weld in t-joint showing good fusion profile at the weld root

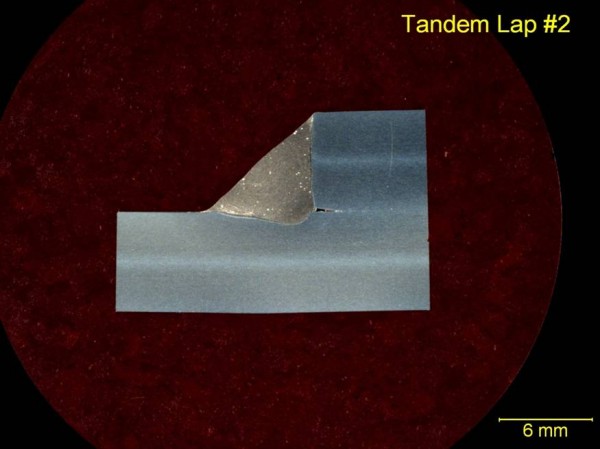

Figure 3 shows the fillet weld in the lap joint configuration, which also exhibits consistency at the weld toes. The fusion at the weld root for this weld, shown in Figure 4, is also ample.

Figure 3. Fillet weld in lap joint configuration

Figure 4. Macro of fillet weld in lap joint showing good fusion profile at the weld root

If you are currently welding aluminum or other metals with GMAW and desire a productivity increase, tandem-GMAW may be an option for you. EWI has acquired expertise on many ways to apply tandem-GMAW and has an in-depth understanding of the interaction of the variables involved. To find out if tandem-GMAW is for you, or if you would like to speak to one of our experts on tandem-GMAW, please contact [email protected] or reach us online.