Introduction

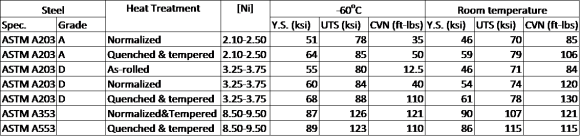

Fabrication of Arctic offshore structures faces a great challenge considering the wind, low temperature (-60oC), impacts from floating ice-blocks, stress from freezing, corrosion, etc. Steel strength, hardness, impact toughness/fracture toughness, and corrosion resistance are major concerns to build an Arctic offshore platform. Knowing that adding more nickel in steels can effectively improve mechanical properties of steels, using nickel steels is natural choice in Arctic. Commercial nickel steels have different levels of nickel contents and heat-treatment experience. The following table presents a summary on three nickel steels, i.e. A203, A353 and A553.  Apparently, mechanical properties of those steels are functions of steels heat-treatment, nickel content, and temperature.

Apparently, mechanical properties of those steels are functions of steels heat-treatment, nickel content, and temperature.

Nickel steel properties

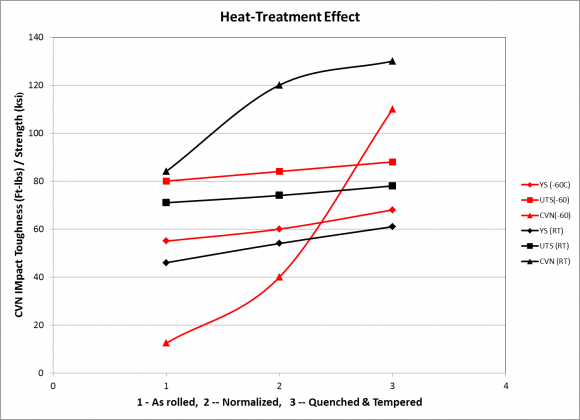

•Effect of steel heat-treatment

The following plot illustrates the relationship between the heat-treatment condition and strength (CVN impact toughness) with respect to different temperatures (room temperature and -60oC) on A203 grade D steels.

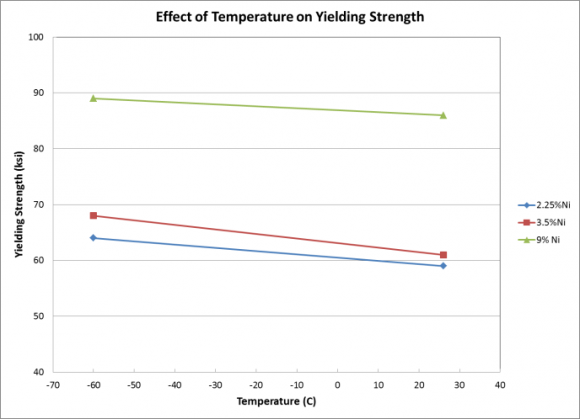

•Effect of temperature

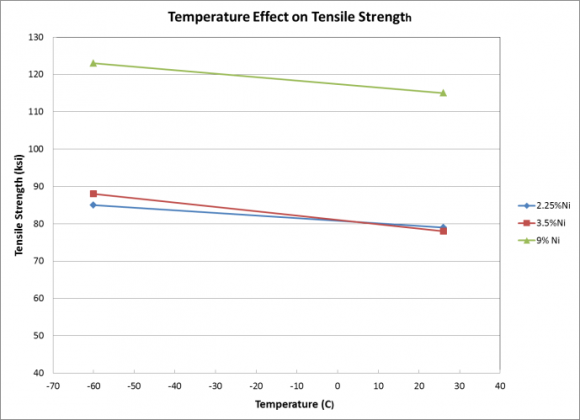

According to the fundamentals of mechanical metallurgy, the steel strength increases while temperature decreases. This is confirmed by the following plots.

•Effect of nickel content

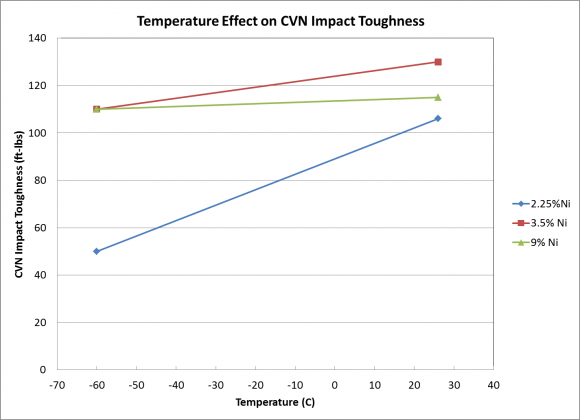

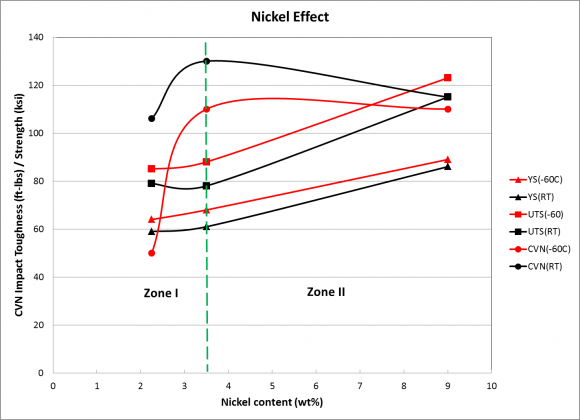

Nickel is an austenite stabilizer that can promote the volume fraction of residual austenite in steel, which in turn to improve the CVN impact toughness. In addition, it is also a moderate solid-solution strengthener and grain refiner. The following plot not only illustrates the benefits from nickel, but also shows its limit.

Challenges of FCAW wires

Based on above, increasing the nickel content up to 9% at -60oC, can reach a 120ksi tensile strength while maintaining an excellent CVN toughness (110 ft-lbs), which is desirable for the Arctic fabrication. However, it brings about a difficult to find a FCAW wire to match the steel properties. Some advanced FCAW wires were tested on AWS-type plate welding and results are shown in the following:

1. For argon-rich gas-shielding FCAW welding The best rutile-based FCAW wire welded at 3G can achieve a 100ksi tensile strength with an 80 ft-lbs CVN impact toughness at -60oC.

2. For CO2 gas-shielding FCAW welding 1) the best rutile-based FCAW wire welded at 3G can achieve a 115ksi tensile strength with a 50 ft-lbs CVN impact toughness at -60oC; 2) the best BaF2-based basic FCAW wire welded at 1G can achieve a 120ksi tensile strength and a 60 ft-lbs CVN impact toughness at -60oC.

3. For self-shield FCAW welding The best frits-based wire can reach a 100ksi tensile strength and a 80 ft-lbs CVN impact toughness at -40oC.

Due to the difference in welding procedures generated by a welding consumable company and a field engineer, results from a consumable company may significantly deviated from the field qualification results. When a FCAW wire does its field-qualification, it is not surprise to see a 20-50% drop of the CVN impact toughness that is reported from its AWS- type plate welding test. If such a reduction in toughness is true for the above wires to be used in Arctic, none of them will be considered to be reliable enough to weld an Arctic steel with a nickel content above 3.5%. Indeed, it brings about a difficult in structure design. Moreover, welds generated from those FCAW wires have a nickel content ranging from 2.5 to 4.0%. The nickel content range is overlapped with the “CVN Sensitive Zone”. To control the sensitivity, it requires that the flux mixes of those FCAW wires need to be well-blended to avoid the segregation of alloying elements. Due to the density difference between nickel powder and other alloying powders in flux mixes, the flux blending is certainly a challenge. Further increasing nickel in a flux mix may significantly increase the liquid slag viscosity. It could degrade the all-position welding characteristics could be degraded and result in unsatisfactory welds. So far, a 4% nickel in a low-alloy steel weld is close to the limit that conventional FCAW wire can offer.

Conclusion

FCAW is proven to be capable of increasing the welding efficiency and reducing the fabrication cost by producing quality welds in conventional environment. The all-position welding characteristics and welding efficiency of FCAW makes the welding process superior to other welding processes. However, considering its limits and short-comings discussed above, a serious investment is needed to collect more evidences and conduct more experiments on Arctic steels welding by using FCAW wires.

References:

[1] S. McCoy, “Corrosion Performance and Fabricability of the New Generation of Highly Corrosion-Resistant Nickel-Chromium-Molybdenum Alloys”.

[2] “Low Temperature Properties of Nickel Alloy Steels”, INCO.