Better Parts, Faster: EWI Unlocks the Future of Electron Beam Metal 3D Printing

How charge-neutral technology is transforming powder bed fusion for high-performance manufacturing

system

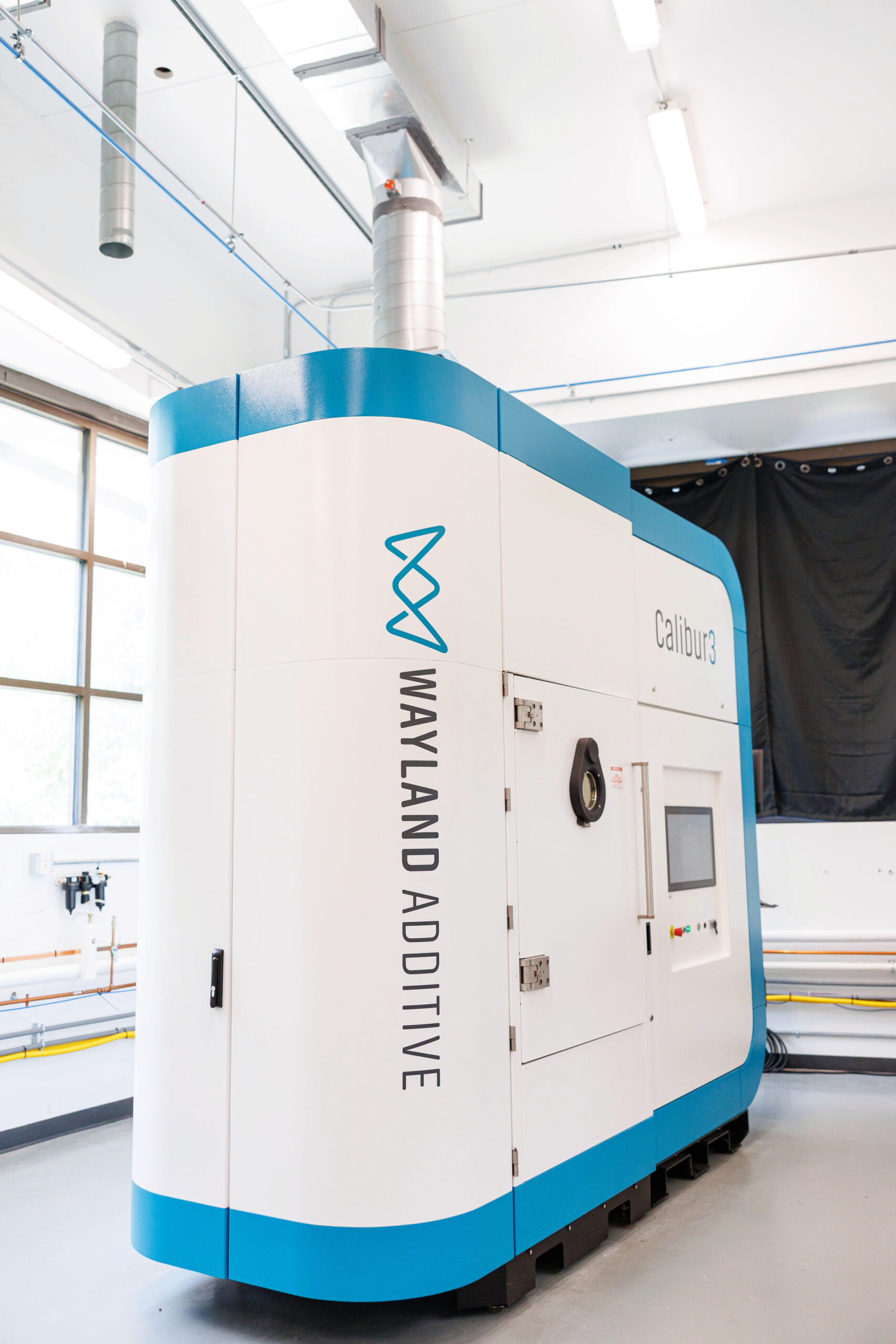

Additive manufacturing is entering a new era, and EWI is proud to be leading the way. With the installation of the Wayland Additive Calibur3® electron beam powder bed fusion (EB-PBF) system at our Buffalo Manufacturing Works facility, EWI is now the only organization in the U.S. with access to this groundbreaking technology.

Thanks to Wayland’s NeuBeam® process, this system introduces a significant advancement in metal 3D printing by removing a major barrier to process stability. This enables faster printing, cleaner parts, expanded material options, and a more efficient powder workflow.

The Advantages of Electron Beam Powder Bed Fusion

Powder bed fusion (PBF) is a proven method for manufacturing high-precision, complex parts in industries such as aerospace, defense, energy, and medical. Laser-based PBF systems are widely used, but electron beam systems bring important benefits that stem from their unique process physics.

Unlike laser systems that use mechanically controlled mirrors, EB-PBF steers its high-energy electron beam magnetically, allowing for extremely fast, precise control. This beam can move orders of magnitude faster than a laser, while also delivering greater energy transfer and deeper penetration.

EB-PBF capability supports higher-temperature builds, larger layer heights, and tighter control over material microstructure. Because the process operates under vacuum, it also reduces oxidation and allows for more consistent results with sensitive materials.

Overcoming the Challenge of Charge Buildup

While EB-PBF offers significant benefits, its adoption has historically been limited by one critical issue. During traditional builds, the electron beam imparts a negative charge on the powder. Over time, this charge builds up, sometimes causing the powder to scatter mid-build. These events, known as “smoking,” can ruin a print and contaminate the chamber.

To avoid this, conventional systems sinter the entire powder layer before melting the part geometry. This approach reduces the chance of smoking but comes with major drawbacks. It makes powder recovery difficult, increases post-processing time, and limits design freedom.

A Charge-neutral Breakthrough with NeuBeam®

Wayland’s NeuBeam technology solves this problem by actively neutralizing the charge buildup during the build process. It introduces a small amount of positively charged argon ions into the chamber, which cancel out the negative charge on the powder.

This innovation eliminates the need to sinter full powder layers and dramatically reduces the risk of smoking events.

system

The result is a cleaner, more efficient, and more scalable EB-PBF process. At EWI, we have already validated the benefits of charge-neutral printing. We’ve completed dozens of successful builds using recycled powder with minimal degradation. This is a critical step toward more sustainable, cost-effective additive manufacturing

Materials and Applications at EWI

The Calibur3 system at EWI has already demonstrated its ability to process both conventional and advanced materials. Highlights include:

- Molybdenum (Mo): A refractory metal with high-temperature capabilities and challenging processing characteristics. Using the Calibur3, EWI achieved near full density prints with minimal porosity.

- Ti64 (Titanium alloy): One of the most common materials in aerospace. EWI produced high-strength parts with complex geometry.

- C103 (Niobium alloy): A material currently under evaluation as part of our ongoing development roadmap.

Because the system does not require full-layer sintering, part removal is much easier and internal features can be more complex. Powder recovery is also cleaner and more efficient, reducing waste and improving cost-effectiveness.

Building What Comes Next

The Calibur3 is not just a machine; it is a platform for innovation. It enables design freedom, process reliability, and material exploration that were previously out of reach in electron beam systems.

Our team at EWI is using this technology to:

- Develop proof-of-concept builds with new alloys

- Optimize microstructure control through build parameters

- Evaluate recyclability and build consistency for real-world production

Manufacturers looking to prototype advanced components, validate AM processes, or transition into full-scale production can benefit from collaborating with our team and tapping into this one-of-a-kind capability.

Get in Touch

EWI is proud to offer the only Wayland Calibur3 system in the U.S. If you are working on high-performance applications that demand better materials, faster throughput, and reliable production, we are ready to partner with you.

Contact Jesse Callanan, Applications Engineer, Additive Manufacturing at [email protected].