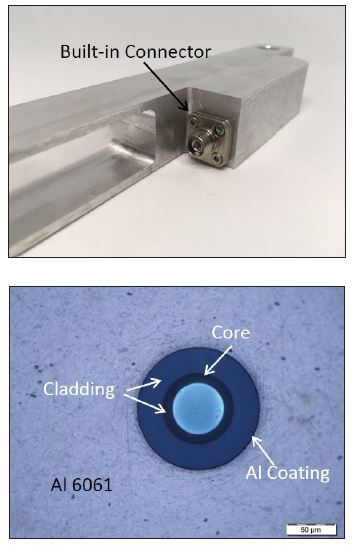

Ultrasonic Additive Manufacturing (UAM), a solid-state (no melting) metal 3D printing technology, enables integration of temperature sensitive components, such as fiber optic strain sensors, directly into metal structures. Sensor integration into metal components is of interest for enhanced control and monitoring purposes of cutting edge components. The technology has relevance in aerospace, nuclear, and oil & gas.

EWI and its affiliate Fabrisonic LLC have pioneered a unique system that utilizes ultrasonic additive manufacturing (a hybrid additive and subtractive manufacturing process) to inlay sensors into system parts as they are being built. The early success of the technology is prompting further study and shows great promise for advancements in the manufacture of sensing systems. Adam Hehr of Fabrisonic has written Building Fiber Optic Strain Sensor into Metal Components, which shares the fundamental work that has been done so far, and offers some of the key areas to be explored using the technology.

To download the paper, click here.

To contact the author, email [email protected].

To learn more about EWI’s work in additive manufacturing, visit ewi.org/technologies/additive-manufacturing.