As performance requirements continue to increase, it is critical that manufacturers have the right methods and support for ensuring that products will perform to specifications. Our team helps our clients boost product performance and reliability through materials development, selection, and characterization; powder processing expertise; measurement and testing capabilities; forensic failure analysis; and coatings and surface engineering technologies.

Three technology-based procedures are particularly critical to identifying and understanding the cause of part failure:

- Optical 3D surface metrology, characterization, and visualization

- Industrial computed tomography

- Scanning electron microscope inspection

Identify. Develop. Implement. At EWI, we know that technology is only as good as the user. Our team possesses the engineering expertise needed to apply these technologies and accurately interpret results. We Manufacture Innovation.

EWI is the brightest group of engineers I have been lucky enough to know.

-L. da Vinci

Why Choose EWI for Metrology?

Failure in a critical part of a supply chain can be catastrophic, but companies often lack adequate in-house testing capabilities to even explain why a product failed. EWI’s metrology team can augment your existing resources to help understand failures, find solutions, and ultimately increase the reliability of products.

Advanced materials engineering, characterization, and testing are critical to these outcomes:

- Performing in-process testing to reduce material costs and improve throughput

- Delivering longer-lasting, higher-quality products

- Implementing net new processes

- Improving past processes

- Understanding and explaining product failure

- Bringing new products to market faster

- Meeting increased customer expectations

- Ensuring compliance with new regulations

Some Ways We Have Helped Our Clients:

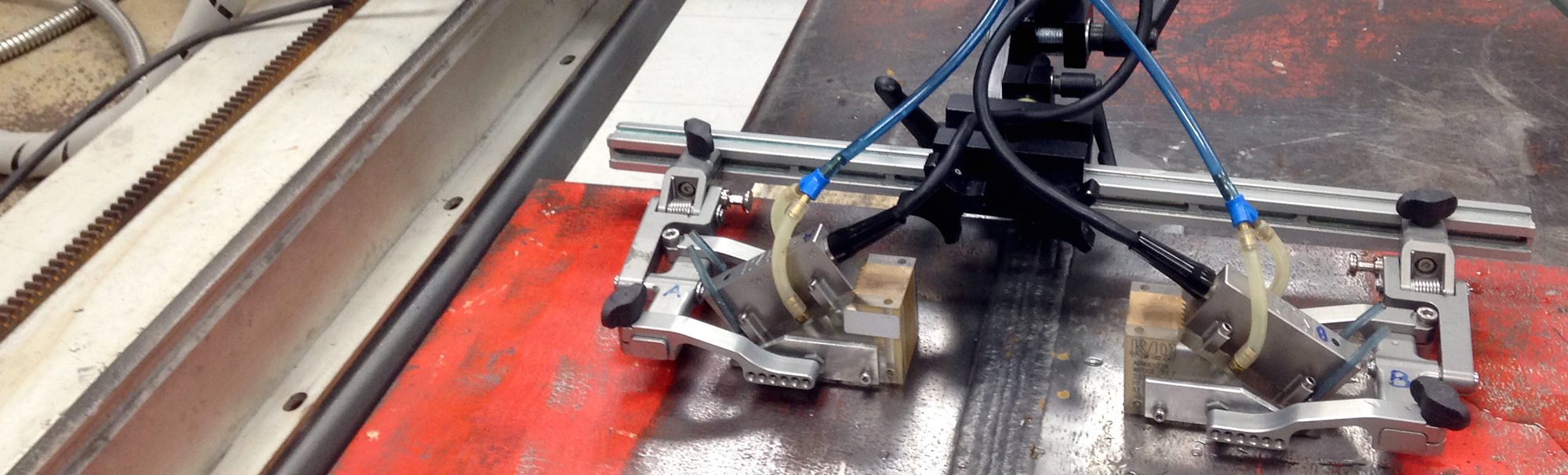

- Automated inspection of sealing surfaces

- Dimensional and cross-sectional analysis of medical device components

- Surface roughness measurement and analysis of dental specimens

- Characterization of powders for additive manufacturing

- Inspection of internal components, critical features, weld joints, burrs, chips

- In situ monitoring for Laser Powder Bed Fusion using digital fringe projection technique

- EWI Adds Metrology Technician to Support Materials Testing Technology Focus Area

Our Metrology Expertise

Detailed measurement of internal features is critical for quality control, failure analysis, and material research across various industries. Industrial computed tomography (CT) is the gold standard in nondestructive evaluation. With CT, the EWI team enables the following:

- Characterization of 3D-printed parts with complex geometries or multi-material builds

- Characterization of composite material

- Failure forensics

- Measurement of internal dimensions without sectioning the sample

- Quality control of metal and plastic parts

- Verification of complex internal structures

Equipment & Capabilities of EWI’s Precision Measurement Lab

- Alicona IF-Robot

- BeckmaCoulter Multi-wavelength Particle Size

- Analyzer and Tornado Module

- Bruker Nano Inc.

- NPFLEX 3D Metrology System

- HexagoMetrology Global Performance Silver

- EditioMetrology Frame (CMM)

- Hitachi High Technologies Ultra Large Chamber

- Variable Pressure SEM

- Machine VisioTest Lab

- NikoXTH 225 and 450

- Novacam Technologies MicroCam-4D

- Profilometer

- PDI PrecisioDevices Surfanalyzer

- Polytec Inc. Laser Vibrometer HSV-100

Meet the Metrology Experts

From characterizing powders for additive manufacturing to completing a dimensional and cross-sectional analysis of medical device components, we’ve met many challenges with an innovative spirit. Our metrology team has the experience, the expertise, and the technology resources needed to understand failures and use those insights to ensure reliable products. We’re excited to learn more about your project.