Ceramics & Ceramic Matrix Composites

Ceramics & Ceramic Matrix Composites

Material characterization and alloy development have been at the core of EWI’s technology development services since our founding in 1985.

What began with metals quickly expanded into plastics and ceramics as increasingly advanced materials became available for manufacturing production.

Many CMCs have exceptional properties such as high thermomechanical, thermochemical resistance, and low density compared to traditional materials are now available on the market. Still, their use is limited due to a lack of reliable joining approaches. Developing effective joining methods is key in the adoption and integration of these materials.

The EWI team uses its broad skills and experience in materials engineering to develop joining solutions for ceramics and CMCs. Some of our work includes:

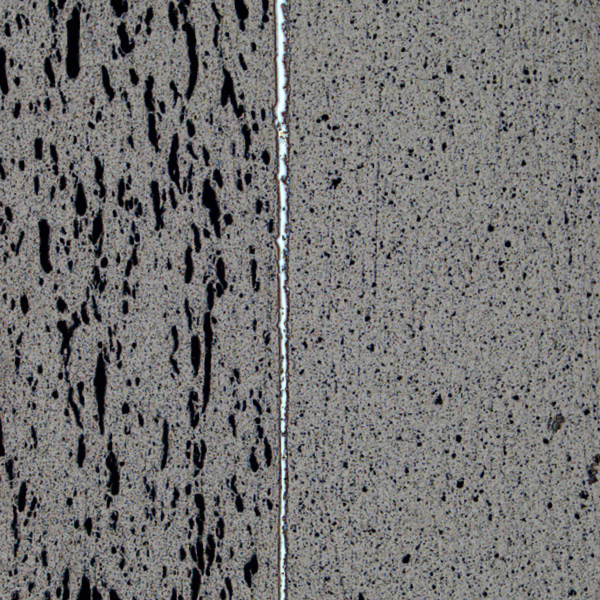

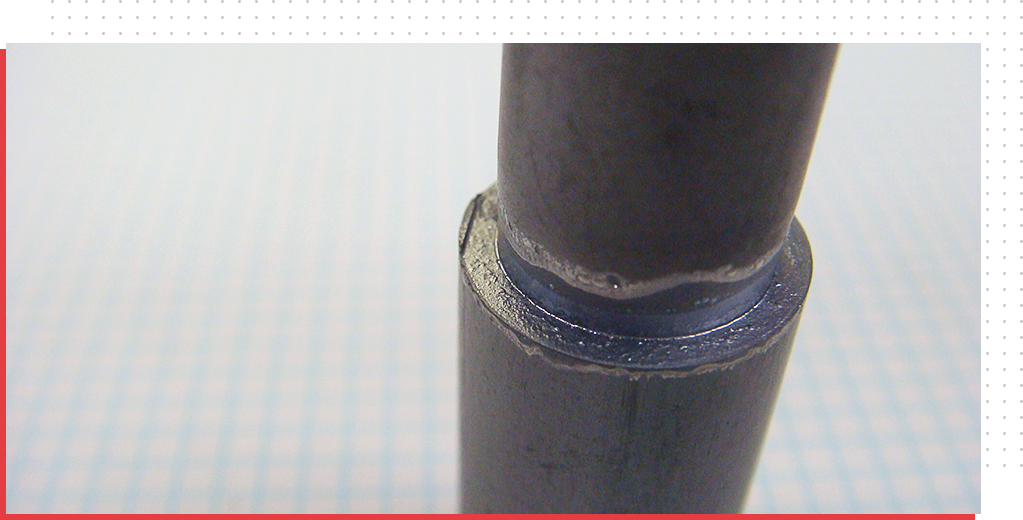

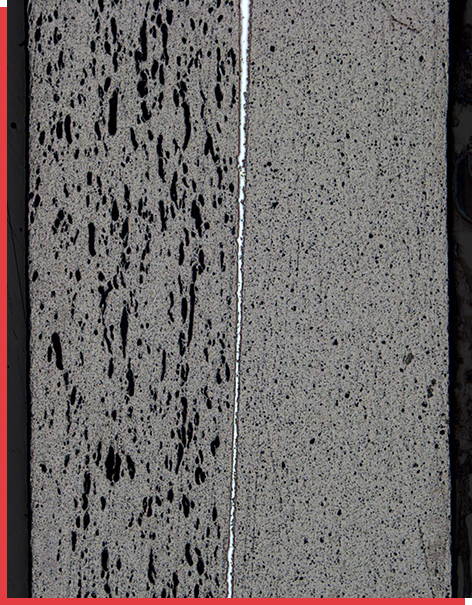

- Inventing a new brazing alloy and methodology to join monolithic SIC to itself and other CMCs

- Developing an alternative heating procedure for brazing CMCs

- Developing a brazing technique for direct bonding of CMCs to metal alloys

Engineering with Integrity

Since 1984

Whether we’re evaluating a new material, defining the fatigue performance capabilities of welded parts, or identifying the cause of an unexpected failure, our team enables your team to design the required materials and testing specifications ensure successful performance, structural integrity, quality, and safety. We provide the assurance you – and your customers – need for your products.

Need help now? Contact EWI today.