Metals & Metal Matrix Composites

Metals & Metal Matrix Composites

The materials engineers at EWI have been providing services to characterize and evaluate metals for more than 35 years.

As new metal alloys and metal matrix composites are developed, manufacturers across all sectors have routinely turned to our team to assess feasibility for use in their applications.

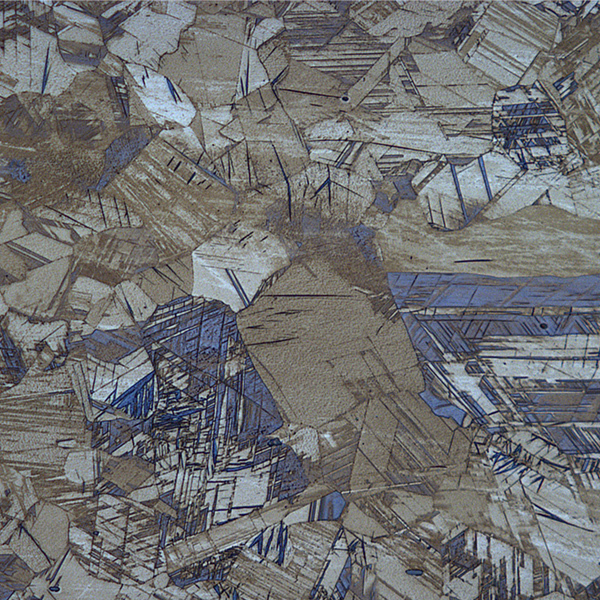

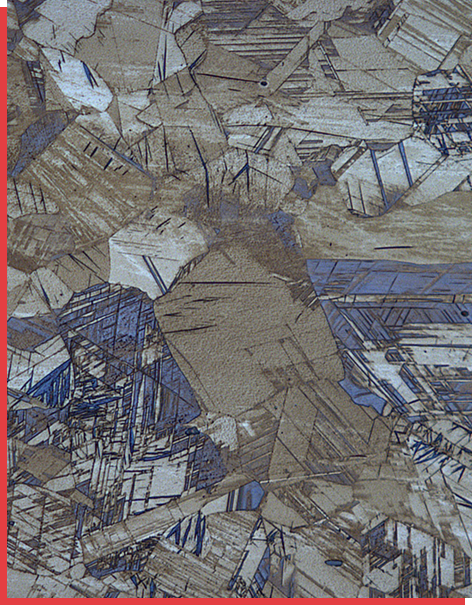

Our specialty areas include ferrous and non-ferrous metallurgy, polymers, adhesives, dissimilar materials joining, heat treatment, material characterization and alloy development, weldability testing, and a deep understanding of the interaction between welding processes and materials to control the resultant material properties. Clients can access this diverse set of skills to address challenges at all stages of their manufacturing processes.

Recent EWI R&D in metals and metal matrix composites include:

- Friction Stir Welding of Metal Matrix Composites

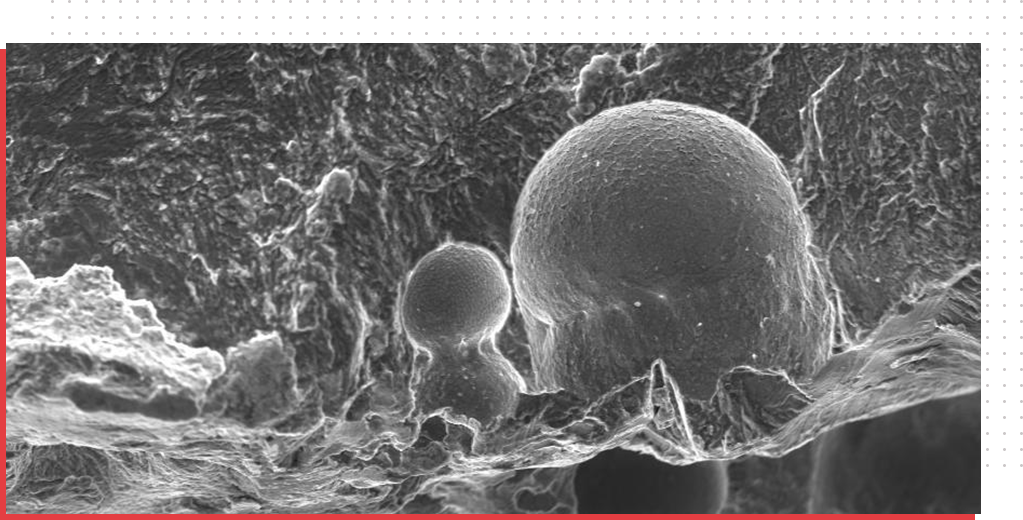

- Laser Powder Bed Fusion (L-PBF) Stirring for Crack Sensitive Alloys

- Resistance Powder Consolidation

- Custom Alloy Mixes for L-PBF of High-strength Aluminum Alloys

- Corrosion Susceptibility for AM Alloys

- Evaluation of Nanoparticle 7075 Alloy for DED Applications

Engineering with Integrity

Since 1984

Whether we’re evaluating a new material, defining the fatigue performance capabilities of welded parts, or identifying the cause of an unexpected failure, our team enables your team to design the required materials and testing specifications ensure successful performance, structural integrity, quality, and safety. We provide the assurance you – and your customers – need for your products.

Need help now? Contact EWI today.