As more industries look toward additively manufactured (AM) components to optimize lead times, cost of complexity, and more, those industries must evaluate the performance of materials produced by AM processes in comparison to their well-documented wrought or machined counterparts. The fact of the matter is that similitude is not a given. While calling it a case of comparing “apples to oranges” may be inflating the issue, it may be prudent to suggest that it’s like comparing “oranges to lemons.” They both share significant similarities, but a glass of lemon juice might be a little difficult to stomach at brunch.

The technical focus in the AM world to date has been largely on the expected mechanical properties: fatigue, toughness, etc. Military, aerospace, and other sectors have identified the need to understand the effects of build defects, surface finish, and process parameters on the performance lifetime and survivability of AM parts. This concern should extend to materials degradation in the use environment. Specifically, many of the qualities inherent to AM components that effect mechanical properties and fracture mechanics also influence susceptibility to localized corrosion events.

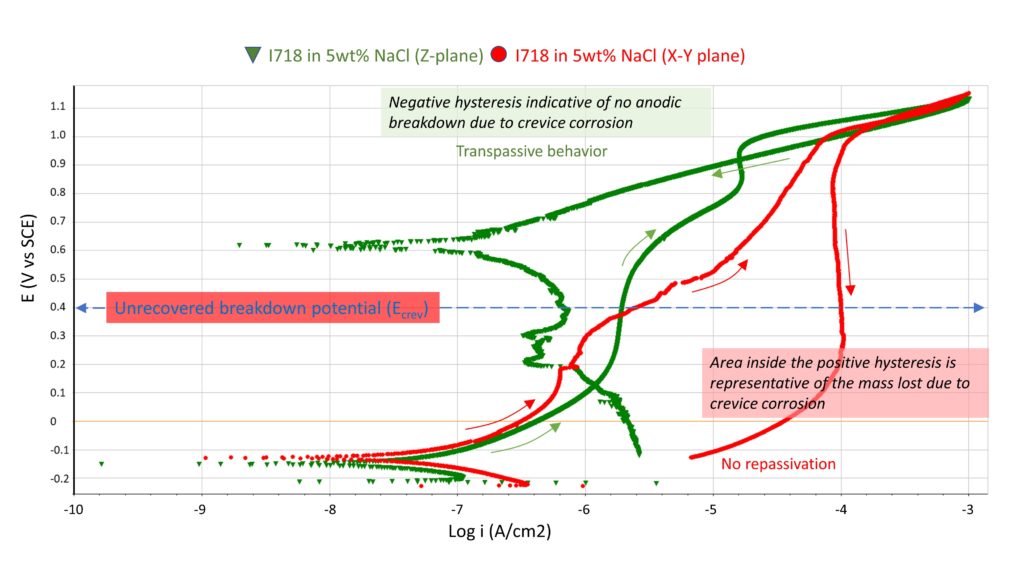

EWI has begun addressing this knowledge gap with an investigation focusing on the effects of processing parameters and standardized post-processing steps typical for laser powder bed fusion (L-BPF) with Inconel 718 (I718). The following plot examines the effect of the direction of the L-PBF build on susceptibility to crevice corrosion.

The cyclic potentiodynamic polarization plot above shows a clear difference in crevice corrosion resistance with respect to cross-sectional orientation, thus assessing the effect of the difference in morphology of the as-built microstructure with respect to build direction. EWI is in a unique position as a multi-disciplinary research organization to help manufacturers adopt AM processes by offering services for building test samples, evaluating microstructure, performing fracture mechanics testing, and qualifying localized corrosion resistance with in-house resources.

To learn more about EWI’s work to address the materials degradation knowledge gaps in additively manufactured components, contact Josh James, EWI Research Leader for Structural Integrity and Materials, at [email protected].