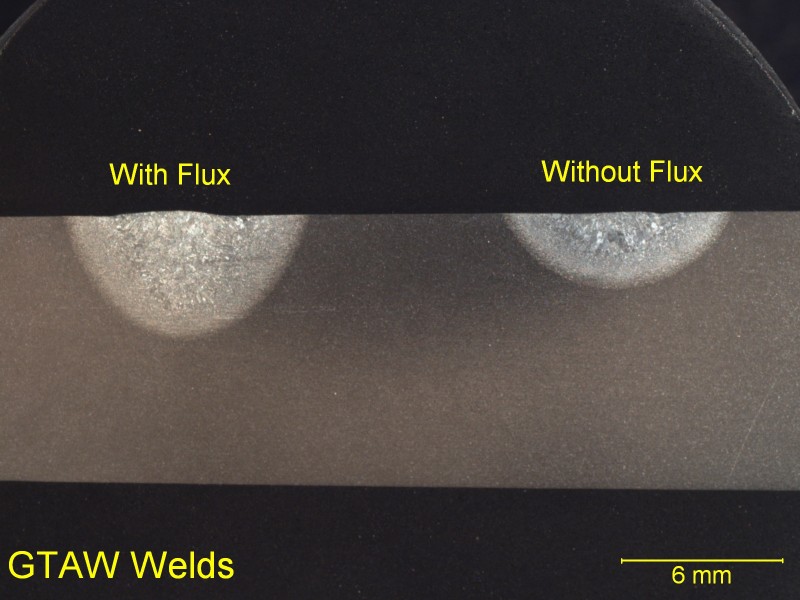

EWI has developed, tested, and now markets compounds that increase the penetration of gas-tungsten-arc-welds (GTAW). These penetration enhancing compounds are marketed under the trade-name EWI DeepTIG. Three different compounds are available: CS-325 for carbon steels, SS-7 for stainless steels, and NI-139 for nickel alloys. A comparison of GTA welds made on A36 steel, with and without the penetration enhancing compound, are shown below. The weld with the penetration enhancing flux clearly has deeper penetration.

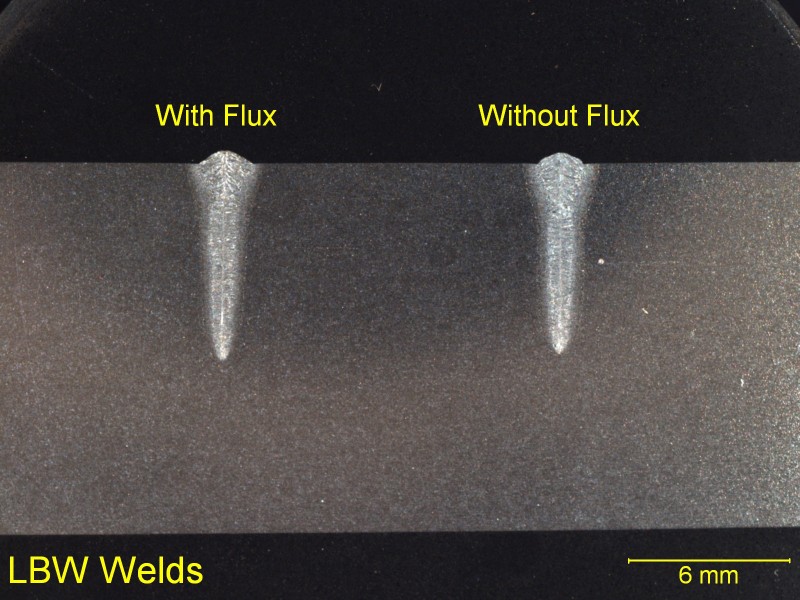

Recently, the question has been raised as to whether or not these compounds could also increase the penetration of laser-beam-welds (LBW), specifically deep penetrating LBWs in the keyhole welding mode. As a result, two welds were made on A36 steel with a laser beam power of 5kW, a 333 micrometer spot size, and a travel speed of 80 ipm; one with and one without penetration-enhancing-compound (PEC). The results from this experiment are presented below; the PEC did not increase the penetration with the LBW process.

When PEC is used with the GTAW process, deeper penetration results from exploitation of the Marangoni effect. The PEC alters the surface tension of the molten metal, altering the fluid flow within the weld-pool, causing the hottest molten metal to circulate downwards, and increasing weld penetration. However, in LBW, deep penetration is derived from the formation of a ‘keyhole’. The intense laser heat source vaporizes the metal in the center of the weld-pool, driving the laser deeper into the material, and creating a very deep narrow weld. Since fluid flow does not strongly influence the keyhole welding mode, PEC does not increase the penetration of LB keyhole welds.

Do you have an interest in deeper penetrating laser welds? Write to us and let us know what your application is. Maybe we can work together on a project to develop PE-compounds specifically for the LBW keyhole welding mode. Can we create compounds that ease the formation and sustainment of keyholes in the LBW process, thereby promoting deeper penetrating welds?