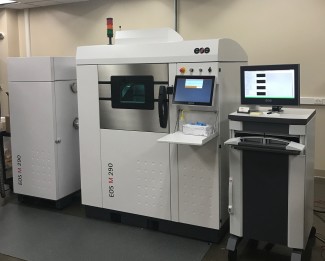

EWI is pleased to announce the acquisition of its second EOS direct metal laser-sintering (DMLS™) system, an additive manufacturing (AM) technology with the capacity to fuse metal powder into 3D components. The newest addition to the EWI AM family is the EOS M290 DMLS System including EOSTATE MeltPool which delivers high-resolution data for process development and quality control. With the installation of the new machine, the EWI AM team is moving into a new, more expansive AM lab at its Columbus, Ohio, facility.

EWI is pleased to announce the acquisition of its second EOS direct metal laser-sintering (DMLS™) system, an additive manufacturing (AM) technology with the capacity to fuse metal powder into 3D components. The newest addition to the EWI AM family is the EOS M290 DMLS System including EOSTATE MeltPool which delivers high-resolution data for process development and quality control. With the installation of the new machine, the EWI AM team is moving into a new, more expansive AM lab at its Columbus, Ohio, facility.

EWI has acquired The EOS “Parameter Editor” module, which offers developers and researchers a large and open tool set ensuring a great freedom for application-specific optimization. “EOS has a long history of quality AM equipment and continues to expand its technical product offerings,” said EWI Senior Technical Advisor Curt Taylor. “The parameter editor will allow us to continue to build on our current material database through characteristics analysis of new materials.”

EWI has acquired The EOS “Parameter Editor” module, which offers developers and researchers a large and open tool set ensuring a great freedom for application-specific optimization. “EOS has a long history of quality AM equipment and continues to expand its technical product offerings,” said EWI Senior Technical Advisor Curt Taylor. “The parameter editor will allow us to continue to build on our current material database through characteristics analysis of new materials.”

To learn more about EWI’s L-PBF and other AM capabilities, contact us.