EWI GUIDE TO DESIGN OF EXPERIMENTS FOR ENGINEERING CHALLENGES

So, you’re assessing a processing technology for your manufacturing system. How do you characterize performance? What assessment tools can be used to make sure the fabrication process you develop will be scalable and efficient on the factory floor?

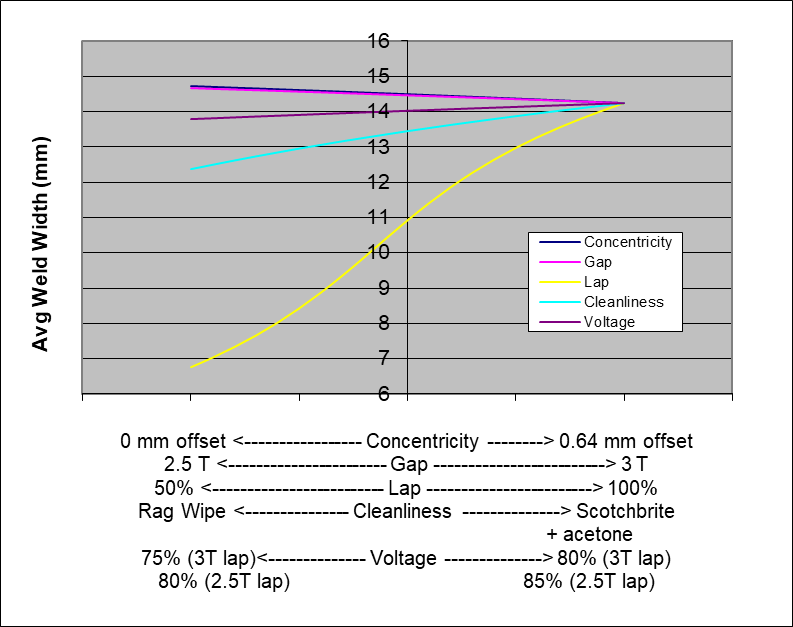

Design of experiments (DOE) methodology offers a statistics-based approach for understanding the behaviors and responses of specific processing technologies when used under a known set of factors. When applied early in manufacturing process development, a DOE model can provide critical information for process optimization, assessments of inherent robustness, and prediction of future performance.

Applying DOE approaches in your technical investigations gives you a head start when developing your new products. To learn more, download The EWI Guide to Design of Experiments for Engineering Challenges. This new resource, written by Senior Technology Leader Jerry Gould, is available for free by filling out the form below:

To find out how you can apply EWI's DOE methodology in your technical investigations right now, contact us at 614.484.7600 or [email protected].

You are the expert for your product. EWI's expertise focuses on manufacturing processes. We look forward to working with you to solve your product development challenges. Give us a call today at 614.484.7600 or fill out a contact form to get in touch with our technical specialists. We can work with you to identify, develop, and implement the right joining solution for your new product.