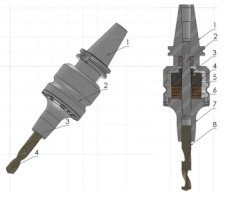

The article titled “Performance of an Ultrasonic-Assisted Drilling Module” discusses how the ultrasonic-assisted drilling module, designed using FEA methods with a 16 mm carbide drill, is used to study the effects of ultrasonics on thrust force, torque, surface quality, hole size, and the microstructure of drilled 4340 steel. Also, discover how ultrasonics vibrations not only can reduce the average values of thrust force and torque but also can improve the surface quality of the hole.

To read the article online, click here. To learn more about this topic, contact Amin Moghaddas at 614.484.7600 or [email protected].