For nearly a decade, EWI has continued to push the envelope in optical solutions for high-power laser welding. As our own lasers grow, so does our need for more robust and stable optics that can perform over extended periods of time. If you are welding with <2 kilowatts and a 1 second cycle time, these optics probably aren’t for you. However, we regularly hear from customers that continue to the fight the focal shift battle when welding at 10+ kilowatts for long weld times. Our answer was to completely eliminate troublesome transmissive optics (including the cover window) and replace them with unique reflective optics.

EWI proved the optics robustness in our first version of the High Power Reflective Focusing Optics (HPRFO) when welding a dozen 12-ft long Inconel 718 panels with 13 kilowatts, flawlessly! The welds took nearly 2 minutes each and passed all D17.1 criteria with flying colors.

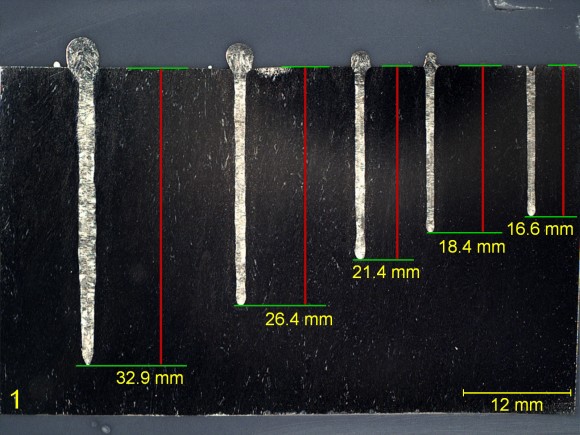

We’ve since moved to a new, more robust version of HPRFO to minimize the complexity and incorporate better plume management and optics protection techniques. The optics were assembled and tested over the past few weeks and the welding results did not disappoint. Welding with 20 kilowatts, we reached nearly 33 millimeters of penetration on a duplex SS alloy. This far exceeds our typical rule of thumb which estimates 1 millimeter of penetration per kilowatt of laser power at 2 m/min. Maybe it’s material related, maybe it’s magic. We have yet to find out but the results are impressive nonetheless. You can find more information on HPRFO2 here.

For more information please contact Blake McAllister (614-688-5166, [email protected]) or Stan Ream (614-688-5092, [email protected]).