The integration of additive technology into all areas of manufacturing – from fabrication to maintenance and repair – has positively exploded in the last few years. The need to develop new additive manufacturing (AM) support services has been constant, and EWI continues to rise to this challenge. Here are some of the AM areas in which we have conducted recent R&D and created new offerings for our manufacturing clients:

- Enabling the Use of Refractories. As more metals are being evaluated for use in AM, refractories (metals with very high melting points) are attractive due to their resistance to heat and wear. Those attributes, however, make them extremely difficult to process. The EWI AM team has established a refractory metals program, conducting research in all AM modalities with materials including molybdenum, niobium, tungsten, tantalum, and other high-entropy alloys. With a base of experience built over more than a decade, we can assist fabricators who want to additively build or repair with this previously unworkable group of metals.

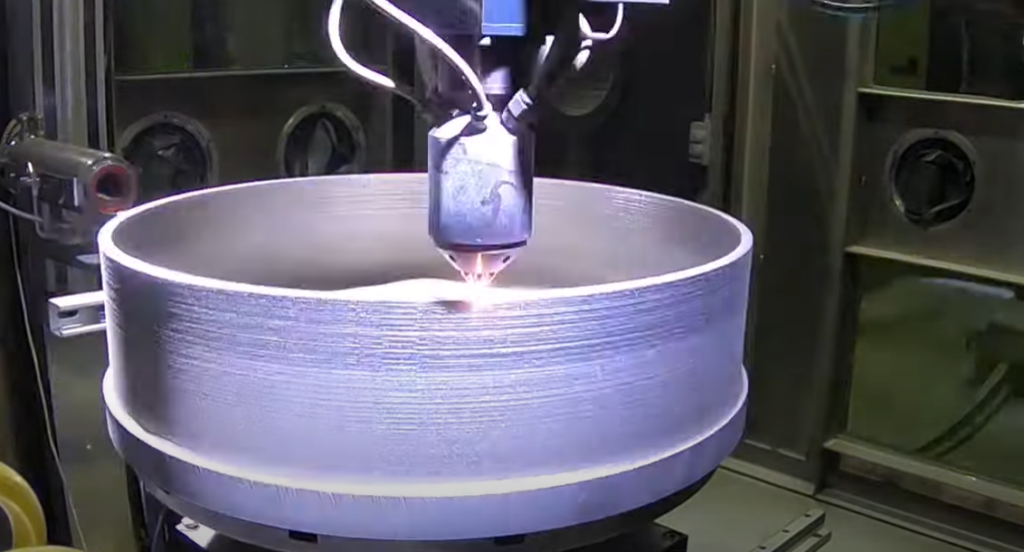

- Furthering FGM Development. EWI has been constructing functionally graded materials on our RPMi 557 system in Buffalo for some time. The objective is to be able to reliably produce a part where the most expensive materials are used only where their special properties are needed, and less expensive materials can be used in the rest of the part. To further address the challenge of working with difficult materials like niobium and nickel, we are applying our deep knowledge of AM processing, monitoring, and data science to carry out FGM development with increasingly tough combinations.

- Monitoring the Health of L-PBF systems. Laser powder bed fusion has been in use to additively manufacture commercial products for many years now. One of the questions we often encounter is, “How do we ensure that a machine is working at its best without stopping production?” EWI has created two systems for in-service L-PBF equipment health monitoring: 1) Laser profile monitoring across a build platform, and 2) gas flow monitoring across a build platform. We use these both of these for maintenance of our own equipment, and after further development and validation plan to offer these solutions to our clients.

Could your company benefit from these developments? EWI is ready to help. Please contact Howie Marotto, AMC Director, at [email protected] or Susan Witt, EWI AM Engineering Group Leader, at [email protected].