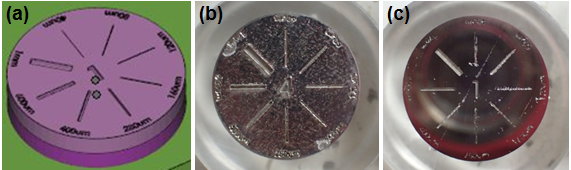

Two categories of flaws were generated, including open-to-surface flaws and embedded flaws, and multiple iterative experiments were conducted. The outcome of this research was an in-depth understanding of how to optimize flaw designs, process parameters, and machine settings to achieve the highest possible levels of dimensional accuracy.

Application Engineer Mahdi Jamshidinia has written Flaw Generation in Laser Powder Bed Fusion Additive Manufacturing to provide an overview of EWI’s work to intentionally create flaws with specific sizes and geometries using the laser powder bed fusion (L-PBF) process. To read the paper, click here.