The Department of Energy has a substantial fleet of nuclear facilities that have reached their end of life or are projected to be at end of life in the near future. Many of these facilities are contaminated with radionuclides, asbestos, lead based paint, or other forms of contamination. These facilities need to be deactivated and decommissioned (D&D) in a manner that is both cost effective and environmentally friendly. According to a committee formed to review DOE’s cleanup technology roadmap there are approximately 3000 such facilities scattered around the United States. Of these, 12 were specifically highlighted as the “most difficult” for D&D. A report titled “Advice on the Department of Energy’s Cleanup Technology Roadmap: Gaps and Bridges” contains the details.

One of the specific areas of concern raised by the DOE committee on cleanup technology was removing contamination from building walls, equipment in the facilities, and other surfaces. Traditionally, contamination removal from metallic and concrete surfaces is accomplished with media blasting. These mechanical stripping techniques result in substantial secondary waste generation comprised of a virtually inseparable collection of the contamination being removed and the media used to remove the contamination.

EWI has been working to demonstrate our advanced laser surface cleaning technology for surface decontamination of structures. This technique is capable of performing decontamination without producing substantial amounts of secondary waste. More information on the technology can be found on the D&D knowledge management information tool: https://www.dndkm.org/Technology/TechnologyFactSheet.aspx?TechnologyID=481

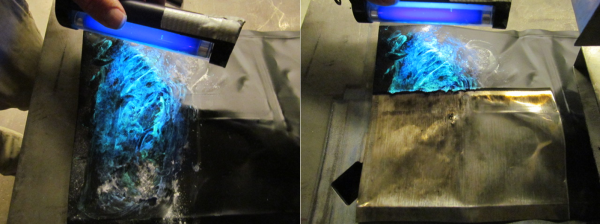

The EWI team recently completed a demonstration on representative non-radioactive materials in partnership with NEWGreen LSI (http://newgreenlsi.com/). NEWGreen LSI is a national leader in decontamination services. The images below show before and after photos of a piece of bent sheet steel that had been painted and then coated with talcum powder. The talcum powder was acting as a simulated contaminant.

The video below shows the process of cleaning the surface shown above and uses a black light to show that there is no residual powder on the surface following the removal process. This was used as a qualitative indication of potential contaminant removal.

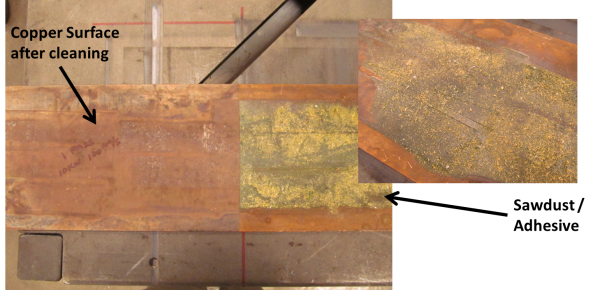

The images below show a copper sheet that has sawdust adhesively bonded to the surface. The type contamination where there is residual adhesive that has collected contaminant dust or particles over many years is common at aging infrastructure sites. During this study, it was demonstrated that the surface could also be cleaned in a single pass.

If you would like more information on this unique process used for decontamination and decoating, please contact Ed Herderick at 614.688.5000 or by email at [email protected].

You may also be interested in some of my other blog posts: